NMM Morpholine | 99.5% Purity, Bulk Supply & Fast Delivery

NMM Morpholine is a key solution in the chemical industry, specifically within Organic chemical manufacturing and Chemical intermediates and catalysts. This article explores how Shijiazhuang Sincere Chemicals Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- NMM Morpholine Overview

- Benefits & Use Cases of NMM Morpholine in Chemical intermediates and catalysts

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on NMM Morpholine from Shijiazhuang Sincere Chemicals Co., Ltd.

NMM Morpholine Overview

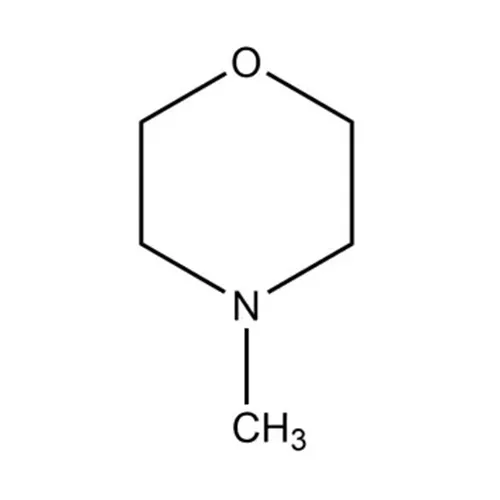

NMM Morpholine (N-methylmorpholine, CAS 109-02-4) is a tertiary amine prized for its balanced basicity and excellent solvating power. With the molecular formula C5H11NO and a typical boiling point around 115–116°C, it is a clear, low-viscosity liquid used across organic synthesis, catalysis, and intermediate production. For B2B decision makers in Organic chemical manufacturing and Chemical intermediates and catalysts, NMM Morpholine offers a dependable base, neutralizing agent, and process aid that improves conversion efficiency and downstream purity. Typical high-purity specifications include assay ≥99.0%, water ≤0.20%, and low color (APHA ≤15), supporting consistent reactivity and reduced byproducts. Density is approximately 0.92 g/cm³ at 20°C, and the product is miscible with many polar solvents, making integration into continuous or batch processes straightforward. Shijiazhuang Sincere Chemicals Co., Ltd. supplies NMM Morpholine with rigorous quality control and responsive technical support, ensuring reliable delivery, document packages (COA, SDS), and packaging options tailored to global logistics.

- Definition and role: NMM Morpholine is a tertiary amine base and process solvent/intermediate vital to catalytic transformations and value-added intermediates in fine chemicals, polymers, and fiber production.

- Technical snapshot: Assay ≥99.0%; water ≤0.20%; b.p. 115–116°C; flash point ~28°C (closed cup); pKaH ~7.4; low metal content—ideal for sensitive reactions.

- Reliable source: Shijiazhuang Sincere Chemicals Co., Ltd. offers stable supply, consistent batch-to-batch performance, and export-ready packaging.

Benefits & Use Cases of NMM Morpholine in Chemical intermediates and catalysts

In Chemical intermediates and catalysts, NMM Morpholine delivers versatile performance. It is widely used as a base and catalyst in acylation, esterification, and silylation, where controlled basicity enhances selectivity and mitigates side reactions. It serves as a neutralizing agent and acid scavenger in active ingredient synthesis for pharmaceuticals and agrochemicals, and as a process base in specialty polymers and coatings. Critically, NMM Morpholine is a key intermediate for N-methylmorpholine N-oxide (NMMO), the solvent enabling Lyocell (cellulosic) fiber production via a closed-loop process. As a co-catalyst or promoter, it can accelerate isocyanate reactions in urethane systems and assist epoxy formulations in reaching targeted cure profiles. Thanks to strong miscibility with polar solvents and a moderate boiling point, NMM Morpholine is easy to recover by distillation, supporting circular solvent strategies. Shijiazhuang Sincere Chemicals Co., Ltd. leverages application know-how to align purity grades with specific process demands, helping customers reduce rework, cut impurity loads, and improve throughput in both batch and continuous operations.

- Applications: Base/catalyst in acylation, esterification, silylation; intermediate to NMMO for Lyocell; neutralizing agent in APIs/agrochemicals; auxiliary base in urethanes and epoxy systems; process solvent in fine chemicals.

- Advantages: High assay, low water and color, efficient recoverability, stable reactivity, and compatibility with stainless steel and glass-lined equipment.

- Supplier edge: Shijiazhuang Sincere Chemicals Co., Ltd. provides consistent quality, tailored packaging, and responsive technical service for scale-up and routine production.

Cost, Maintenance & User Experience

Total cost of ownership for NMM Morpholine hinges on purity, recovery, and uptime. High assay and low water content reduce side reactions and downstream purification, translating into higher yields and fewer off-spec batches. Its moderate boiling point enables economical recovery by simple distillation; many plants implement closed-loop reuse to minimize fresh amine consumption and waste treatment charges. Packaging options such as 160–170 kg steel drums and IBCs balance freight economics and storage footprint. With proper storage (cool, dry, and well-ventilated; away from oxidizers; tightly sealed), shelf life is excellent, and quality drift is minimal. B2B users in organic manufacturing report smoother reaction control, stable titration baselines, and cleaner product color when switching to high-purity NMM Morpholine, improving cycle times and first-pass quality. Shijiazhuang Sincere Chemicals Co., Ltd. supports cost optimization through consistent quality, on-time shipments, and documentation that accelerates qualification. For maintenance and safety, employ standard amine handling practices: closed transfer, splash protection, local ventilation, and routine water and color monitoring. If moisture ingress occurs, drying via molecular sieves or gentle vacuum is straightforward, helping preserve catalytic performance and ROI across campaigns.

- TCO drivers: Yield, recoverability, fewer reworks, and logistics-optimized packaging.

- User experience: Consistent base strength, easy distillation/reuse, and predictable process control in batch and continuous settings.

Sustainability & Market Trends in chemical industry

Sustainability priorities are reshaping solvent and catalyst choices. NMM Morpholine underpins the production of NMMO—the solvent enabling Lyocell fiber, a cellulose technology with highly efficient solvent recovery (>99% in mature systems) and a lower environmental footprint versus older viscose routes. In fine chemicals, recoverable tertiary amines like NMM Morpholine help manufacturers reduce VOC emissions, amine make-up, and wastewater load. Regulatory momentum (e.g., toward safer processing aids and enhanced traceability) favors suppliers who can provide robust documentation and support greener operations. Market demand is buoyed by growth in cellulosic fibers, specialty polymers, and high-purity intermediates across Asia, Europe, and the Americas. Shijiazhuang Sincere Chemicals Co., Ltd. positions customers for these trends with consistent quality, batch traceability, and guidance on storage, recovery, and safe handling. The company’s focus on reliable supply and customer-centric technical service enables partners to implement closed-loop practices, cut waste, and meet internal EHS targets—without sacrificing performance or throughput.

- Sustainability: Supports circular solvent use and closed-loop fiber production when converted to NMMO; facilitates solvent recovery strategies in fine chemicals.

- Forward-looking supply: Shijiazhuang Sincere Chemicals Co., Ltd. aligns quality, logistics, and technical support to help customers meet compliance and decarbonization goals.

Conclusion on NMM Morpholine from Shijiazhuang Sincere Chemicals Co., Ltd.

NMM Morpholine delivers dependable performance as a base, catalyst, and intermediate across organic manufacturing and Chemical intermediates and catalysts. Its high purity, easy recoverability, and versatile compatibility help improve yields, reduce waste, and streamline operations. Backed by Shijiazhuang Sincere Chemicals Co., Ltd., buyers gain consistent quality, responsive support, and packaging tailored to global supply chains. Ready to evaluate NMM Morpholine for your next campaign? Contact us: email: sjzchx@sjzchx.com — Visit our website: https://www.sincerechemicals.com

- Value recap: Efficiency, selectivity, and recoverability for modern chemical processes.

- Supplier credibility: Shijiazhuang Sincere Chemicals Co., Ltd. is a trusted partner to B2B manufacturers worldwide.

- Strong CTA: Contact us: email: sjzchx@sjzchx.com — Visit our website: https://www.sincerechemicals.com

Post time: Nov . 03, 2025 14:50