NMM Morpholine: High-Purity Catalyst & Base, Fast Delivery

Practical Guide to NMM Morpholine for Industrial Formulators

If you work in PU foams, advanced coatings, or fine chemicals, you’ve bumped into NMM Morpholine (aka N-Methylmorpholine). It’s one of those unsung tertiary amines that quietly makes lines run faster, cures cleaner, and—surprisingly often—simplifies neutralization steps. I’ve watched more than one foam plant shave a few seconds off demold time just by tightening specs on NMM Morpholine.

What It Is (and how it’s made in practice)

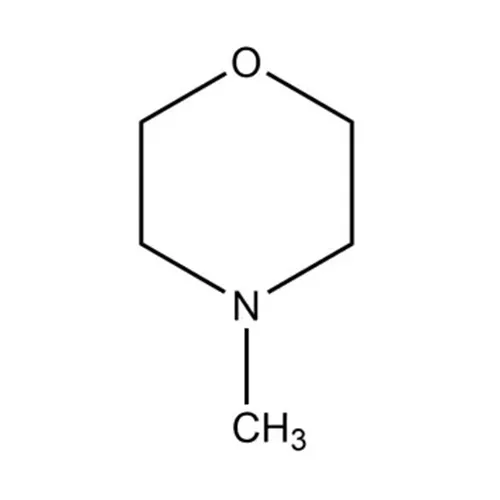

Short description from the supplier is straightforward: colorless liquid tertiary amine, CAS 109-02-4, MW 101.15. The empirical formula is commonly reported as C5H11NO (you’ll sometimes see C4H9ON on older data sheets—ring shorthand; the molar mass confirms the former). Industrial production typically follows vapor-phase N-methylation of morpholine using methanol over a Cu/Ni catalyst, then fractional distillation—QC—packaging. Real-world steps:

- Materials: morpholine, methanol; hydrogen for catalyst conditioning.

- Method: catalytic N-alkylation (vapor-phase), controlled residence time.

- Purification: multi-stage distillation; water and heavies purged.

- QC testing: GC purity, water by KF, color (APHA), density, RI.

- Packaging: drums/IBCs; nitrogen blanket is common for quality.

Specification Snapshot

| Item | Typical Spec (≈) | Test Method |

|---|---|---|

| CAS | 109-02-4 | — |

| Empirical formula | C5H11NO (some sheets note C4H9ON) | — |

| Molecular weight | 101.15 g/mol | — |

| Appearance | Colorless liquid | Visual |

| Purity (GC) | ≥ 99.5% | GC, in-house/ASTM D5134 equiv. |

| Water | ≤ 0.10% | Karl Fischer, ASTM E203 |

| Color | ≤ 20 APHA | ASTM D1209 |

| Density (20 °C) | 0.91–0.93 g/cm³ | ASTM D4052 |

| Refractive index nD20 | 1.433–1.438 | ASTM D1218 |

| Shelf life | 24 months (sealed, cool, dry) | Retain analysis |

| Origin | Jinling Mansions No.106-1 East Yuhua Rd., Shijiazhuang, Hebei, China | — |

Where it’s used (and why)

- PU foam catalyst: slabstock and molded; balances cream/gel times, cleaner cell structure.

- Acid scavenger/base: epoxy hardeners, ink resins, specialty monomer neutralization.

- Solvent/processing aid: extractive steps in pharma/intermediates (check GMP policies).

- CO2/H2S treatment blends and corrosion inhibitor packages (select systems).

Many customers say switching to tighter-moisture NMM Morpholine reduced batch variability, especially in summer humidity. Flash point sits around 27–32 °C (closed cup), so—yes—handle like a flammable liquid and follow your SDS.

Testing standards and data customers actually use

Typical COA includes GC purity, KF water, APHA color, density, and RI. Some labs add amine titration (ASTM D2074 or JIS K1555 equivalent). Color stability after 7 days at 40 °C is often checked in validation runs; real-world drift is minimal if drums stay sealed and dry.

Vendor comparison (quick view)

| Vendor | Purity ≈ | Moisture ≈ | Compliance | Lead Time | Notes |

|---|---|---|---|---|---|

| Sincere Chemicals | ≥99.5% | ≤0.10% | ISO 9001/14001; REACH-ready | 7–14 days | Good QC comms; custom drums/IBCs |

| Global brand (e.g., Lupragen N 105) | ≥99.5% | ≤0.10% | Global SDS/registrations | 2–5 weeks | Broad tech support; premium pricing |

| Local distributor | 99.0–99.5% | ≤0.20% | Varies | Stock-dependent | Fast delivery; spec variability |

Customization and packaging

- Moisture-tight specs (≤0.05%) on request; nitrogen-blanketed fills.

- 170–180 kg drums or 850–1000 kg IBCs; palletized for export.

- Stabilizer packages available (ask for test data; real-world need may vary).

Mini case study: PU slabstock foam

A Southeast Asia foam line swapped to tighter-moisture NMM Morpholine and adjusted the tertiary amine package by 0.05 pphp. Result: ≈8% faster demold, 15–20 APHA lower initial yellow index drift over 7 days (40 °C storage), and—this surprised them—more consistent cream times on humid days. Caveat: your formulation matrix will dictate the exact deltas.

Safety and compliance (quick notes)

GHS: flammable liquid (Cat 3), eye/skin irritant—check your SDS. For pharma-adjacent uses, ask for impurity profiles and residual solvent data. Many buyers want ISO 9001/14001, plus REACH/TSCA coverage; Sincere typically provides these on request.

Authoritative references

Post time: Oct . 27, 2025 17:10