NMM Morpholine | High-Purity N-Methylmorpholine, Fast Supply

NMM Morpholine is a key solution in the chemical industry, specifically within Organic chemical manufacturing and Chemical intermediates and catalysts. This article explores how Shijiazhuang Sincere Chemicals Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- NMM Morpholine Overview

- Benefits & Use Cases of NMM Morpholine in Chemical intermediates and catalysts

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on NMM Morpholine from Shijiazhuang Sincere Chemicals Co., Ltd.

NMM Morpholine Overview

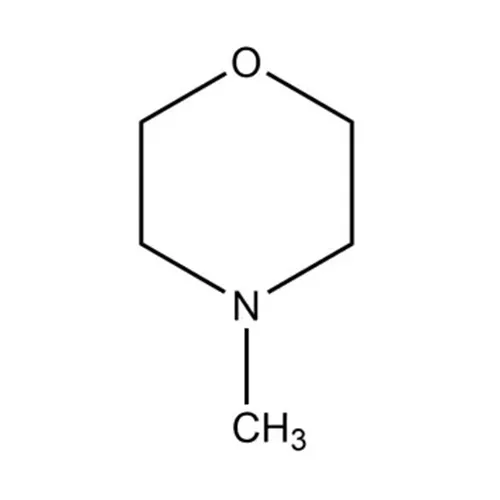

N-Methylmorpholine (commonly referred to as NMM Morpholine) is a tertiary amine widely used as a catalyst, base, and process auxiliary across organic chemical manufacturing. With a typical molecular formula of C5H11NO and a molecular weight of about 101.15 g/mol, it presents as a colorless, low-viscosity liquid with a characteristic amine odor. In production environments, it is valued for its controlled basicity, miscibility with many organic solvents, and reliable performance in reactions requiring clean neutralization or catalytic acceleration. Typical industry specifications include high assay (≥99%), low water content, and low color (APHA), supporting consistent downstream quality.

NMM Morpholine’s boiling range is around the mid-110s °C with a low flash point, reinforcing standard flammable-liquid handling measures. From pharmaceutical intermediate synthesis to polyurethane systems and specialty coatings, its role spans acid scavenging, gelling catalysis, and base-mediated transformations. Shijiazhuang Sincere Chemicals Co., Ltd. supplies NMM Morpholine with rigorous quality control, timely logistics, and documentation (COA/SDS), ensuring predictable performance in pilot and plant-scale operations for B2B buyers seeking a dependable, application-ready amine.

Benefits & Use Cases of NMM Morpholine in Chemical intermediates and catalysts

In chemical intermediates and catalysts, NMM Morpholine plays three primary roles. First, as a tertiary amine base, it efficiently neutralizes acids during acylation, esterification, and peptide-coupling steps, helping maintain reaction rates and selectivity. Second, as a polyurethane catalyst, it supports gelling reactions in rigid foams, elastomers, and CASE applications, contributing to consistent cell structure and cure profiles. Third, it acts as a processing aid or scavenger in specialty syntheses, minimizing side reactions and facilitating cleaner work-ups.

Competitive advantages of NMM Morpholine from Shijiazhuang Sincere Chemicals Co., Ltd. include tight purity and moisture control, stable supply, and application-focused technical support. These enable lower impurity carryover, smoother scale-up, and reduced rework in GMP-adjacent and industrial settings. For B2B decision makers, this translates into predictable throughput and consistent catalyst behavior across batches. Whether your priority is foam reactivity balance, high-yield intermediate production, or streamlined neutralization, Sincere Chemicals aligns product quality and delivery reliability to your operating window. Explore detailed specifications and packaging options on the dedicated product page to align NMM Morpholine with your current formulations.

Cost, Maintenance & User Experience

Total cost of ownership for NMM Morpholine hinges on more than unit price. High assay, low moisture, and consistent color index reduce off-spec risks and downstream purification, improving overall yields and cycle time. In catalyst applications, consistent amine strength helps maintain predictable reactivity, enabling leaner formulations and fewer adjustments on the line. For many producers, the ROI appears in lower rework rates, fewer batch deviations, and improved asset utilization rather than just raw-material savings.

Maintenance and handling are straightforward: store NMM Morpholine in tightly closed containers, away from ignition sources, in dry, well-ventilated areas. Use compatible materials (e.g., stainless steel), and protect from moisture and CO2 ingress. Shijiazhuang Sincere Chemicals Co., Ltd. offers common industrial packaging (drums and IBCs) with clear labeling, COA/SDS, and guidance for closed-loop transfer to minimize emissions. Feedback from organic manufacturing customers highlights smooth qualification, predictable batch-to-batch performance, and responsive service—especially valuable during scale-up or when harmonizing catalyst packages across multi-site operations.

Sustainability & Market Trends in chemical industry

Sustainability priorities are reshaping amine selection and handling. Tighter VOC management, process safety, and waste minimization are now standard expectations across pharma intermediates, polyurethane value chains, and specialty chemicals. NMM Morpholine supports efficient chemistry—its reliable catalytic activity and neutralization efficiency can help reduce overuse of reagents and limit reprocessing. Best practices such as closed transfer, recovery by distillation where feasible, and robust emissions controls further reduce environmental footprint and improve operator safety. Compliance with evolving regulations and transparent documentation remain critical for global supply.

Shijiazhuang Sincere Chemicals Co., Ltd. positions NMM Morpholine within a forward-looking supply strategy: dependable quality systems, proactive regulatory support, and logistics designed to minimize delays and wastage. The company emphasizes continuous process improvement and customer collaboration to meet tightening EHS expectations. As demand grows in construction, automotive, and life-science intermediates, secure sourcing of amines like NMM Morpholine becomes a strategic lever—balancing performance, compliance, and sustainability across the full product lifecycle.

Conclusion on NMM Morpholine from Shijiazhuang Sincere Chemicals Co., Ltd.

NMM Morpholine is a versatile, high-value choice for chemical industry professionals working in organic manufacturing, intermediates, and catalyst systems. Its controlled basicity, consistent purity, and broad compatibility enable efficient reactions, reliable foam catalysis, and cleaner process outcomes. Backed by Shijiazhuang Sincere Chemicals Co., Ltd., customers gain stable quality, solid documentation, and attentive support from qualification to bulk supply. Ready to optimize your formulations and secure reliable sourcing? Contact us: email: sjzchx@sjzchx.com. Visit our website: https://www.sincerechemicals.com

Post time: Nov . 11, 2025 17:25