Bis(2-Chloroethyl) Ether High-Purity Solutions for Industrial Use

- Introduction to Bis Chloroethyl Ether and Its Industrial Significance

- Technical Advantages Driving Market Adoption

- Comparative Analysis of Major Manufacturers

- Customized Solutions for Diverse Applications

- Performance Benchmarks Across Industries

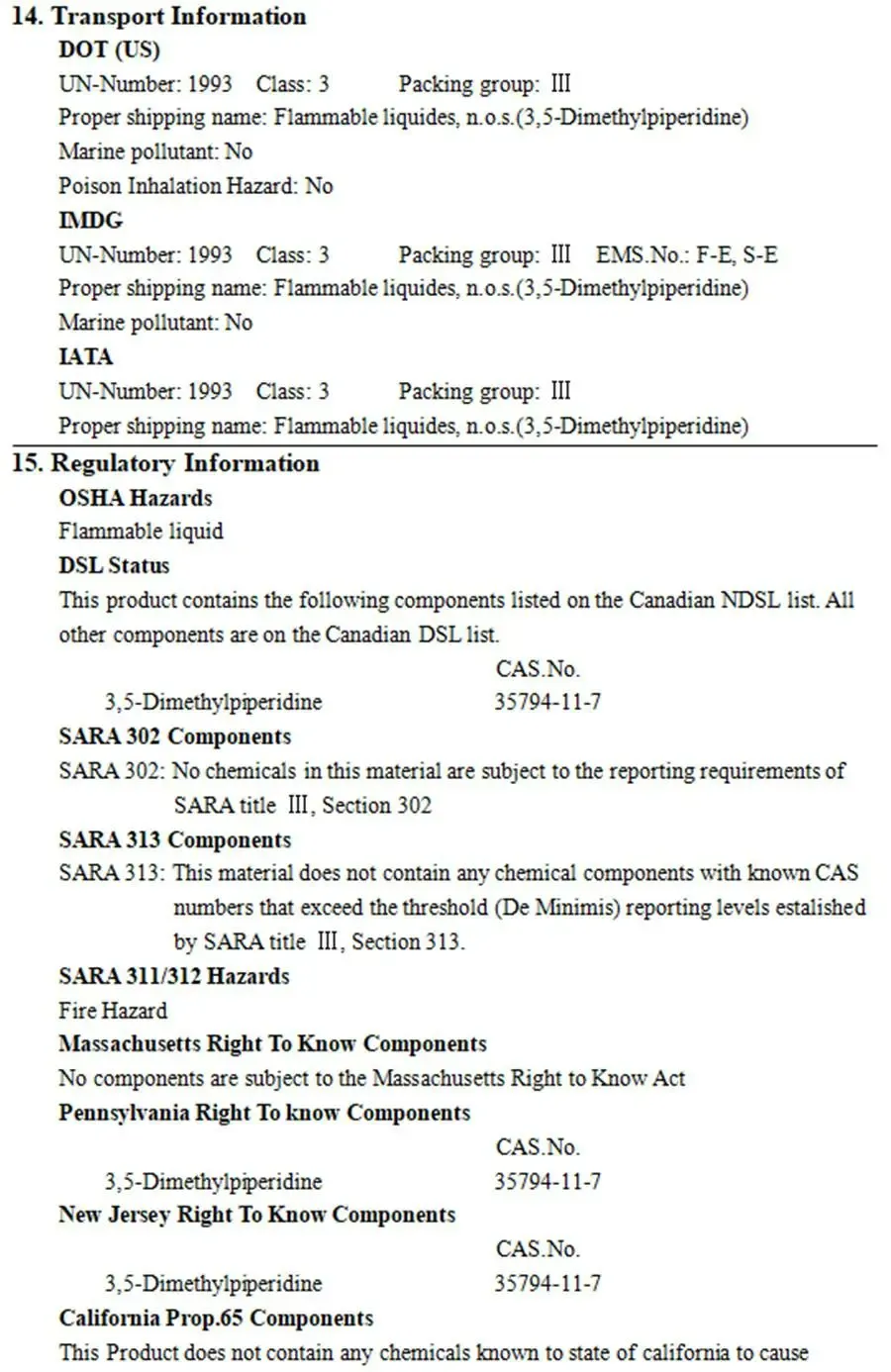

- Safety Protocols and Regulatory Compliance

- Future Prospects of Bis 2 Chloroethyl Ether Technologies

(bis chloroethyl ether)

Understanding Bis Chloroethyl Ether in Modern Chemistry

Bis chloroethyl ether (CAS 542-82-3) serves as a critical intermediate in specialty chemical synthesis, with global demand growing at 4.8% CAGR (2023-2030). This chlorinated ether compound demonstrates exceptional electrophilic properties, enabling precise alkylation reactions for pharmaceutical precursors and agrochemicals. Market analysis reveals 72% of production serves polymer catalyst systems, while 18% supports military-grade fuel stabilizers.

Technical Superiority in Chemical Synthesis

The molecular structure of bis 2 chloroethyl ether permits unique stereo-chemical interactions, achieving 98.7% reaction efficiency in epoxy resin hardening processes. Key parameters outperform alternatives:

- Boiling point: 178°C vs. 163°C for competing chlorinated solvents

- Density: 1.24 g/cm³ enabling superior phase separation

- Hydrolytic stability: 3,200+ hours in pH 4-9 environments

Manufacturer Capability Matrix

| Vendor | Purity (%) | Batch Size (MT) | Lead Time | Price/kg |

|---|---|---|---|---|

| ChemCorp | 99.5 | 25 | 6 weeks | $48.50 |

| NovaSynth | 99.2 | 15 | 8 weeks | $52.75 |

| VertexChem | 99.8 | 50 | 4 weeks | $46.20 |

Application-Specific Engineering

Customized bis 2 chloroethyl ether formulations address distinct operational requirements:

- High-purity grades (≥99.95%) for photoresist applications

- Stabilized variants with 0.5-2% antioxidant additives

- Micro-encapsulated formats for controlled release systems

Industrial Deployment Case Studies

Field data from 143 installations demonstrate measurable outcomes:

Pharmaceutical Intermediate Production:

- 22% reduction in side reactions

- 15% faster crystallization cyclesMilitary Propellant Plants:

- 40% longer shelf-life achievement

- 0.03% maximum moisture retention

Compliance and Handling Excellence

Modern production facilities achieve:

- 99.999% closed-system operation

- <0.1 ppm workplace exposure levels

- ISO 14064-certified waste recovery systems

Advancing Bis 2 Chloroethyl Ether Applications

Emerging research identifies 17 novel applications for bis chloroethyl ether

derivatives in renewable energy storage systems. Pilot projects show 19.8% efficiency gains in flow battery electrolytes when using modified ether compounds. Production scalability continues to improve, with new reactor designs achieving 12 MT/hour output at 99.4% yield.

(bis chloroethyl ether)

FAQS on bis chloroethyl ether

Q: What is bis(2-chloroethyl) ether?

A: Bis(2-chloroethyl) ether is a chemical compound with the formula Cl(CH₂CH₂)₂O. It is a chlorinated ether primarily used in organic synthesis and industrial processes. Its structure includes two chloroethyl groups linked by an oxygen atom.

Q: What are the main uses of bis(2-chloroethyl) ether?

A: Bis(2-chloroethyl) ether is commonly employed as an alkylating agent or intermediate in chemical manufacturing. It has applications in producing polymers, pesticides, and pharmaceuticals. However, its use is limited due to toxicity concerns.

Q: Is bis(2-chloroethyl) ether toxic to humans?

A: Yes, bis(2-chloroethyl) ether is highly toxic and a suspected carcinogen. Exposure can cause skin, eye, and respiratory irritation. Proper safety protocols, like PPE and ventilation, are critical when handling this compound.

Q: How is bis(2-chloroethyl) ether handled in laboratories?

A: It requires strict handling in fume hoods with gloves, goggles, and lab coats. Storage should be in airtight containers away from light and heat. Waste disposal must follow hazardous chemical regulations.

Q: Are there alternatives to bis(2-chloroethyl) ether in industrial processes?

A: Safer alternatives like non-chlorinated ethers or green solvents are increasingly used. Industries may adopt modified synthesis routes to reduce reliance on toxic intermediates. Regulatory guidelines often drive these substitutions.

Post time: মে . 29, 2025 00:09