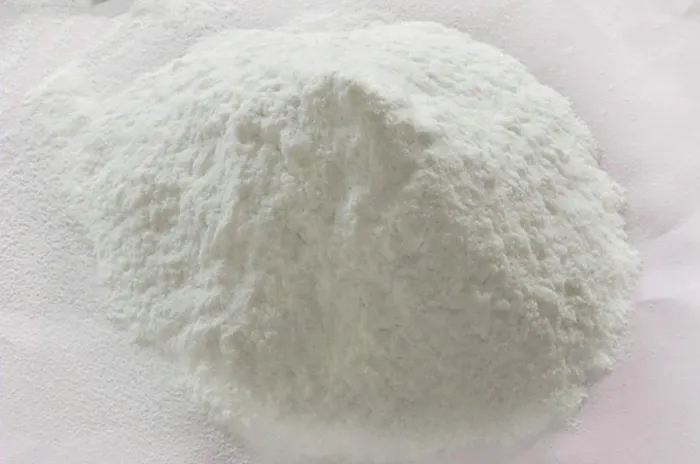

sodium carboxy methyl cellulose uses

Environmental concerns and sustainability goals have also spotlighted the role of CMC in paper production. Here, its use is pivotal in improving paper quality. Sodium carboxymethyl cellulose improves the water retention properties of paper pulp, enhancing the quality and smoothness of paper products while also reducing the consumption of raw materials and energy during manufacturing. This translates into lower operational costs and a reduced environmental footprint, aligning with the increasing demand for sustainable practices. Further broadening its application portfolio, sodium carboxymethyl cellulose is increasingly pivotal in the oil drilling industry. It acts as a rheology modifier in drilling fluids, providing substantial improvements in fluid viscosity and stability under high-temperature and high-pressure conditions. This ensures enhanced performance of drilling operations and minimizes the risks of equipment damage, underpinning its indispensable contribution to efficient resource extraction. In household cleaning products, CMC’s capacity to modulate viscosity and stabilize emulsions is instrumental. It aids in homogenizing cleaning agents, bolstering their efficiency and enhancing user satisfaction through consistency and ease of use in formulations such as detergents and dishwashing liquids. In conclusion, sodium carboxymethyl cellulose continues to stand as a cornerstone material responsive to industry demands for versatile, efficient, and sustainable ingredients. Its integration across a broad spectrum of applications not only testifies to its fundamental properties but also highlights its potential to meet future challenges. As industries evolve, the adaptability and performance index of sodium carboxymethyl cellulose ensures its lasting relevance as a key asset within innovative product development. Whether improving the therapeutic efficacy of medications, enhancing food quality, or enabling sustainable industrial processes, CMC represents the epitome of an ingredient that blends innovation with performance reliability.

Post time: Gen . 26, 2025 03:57