Triethylenediamine (TEDA) Catalyst: High-Purity for PU Foams

As a cornerstone in advanced materials chemistry, Triethylenediamine (TEDA), also known by its IUPAC name 1,4-diazabicyclo[2.2.2]octane or common trade name DABCO, stands as a highly effective and versatile tertiary amine catalyst. Its unique bicyclic structure grants it exceptional catalytic activity, particularly in polyurethane foam production, where it plays a critical role in balancing gelling and blowing reactions. This comprehensive overview delves into the technical intricacies, market dynamics, and strategic applications of Triethylenediamine (TEDA), targeting B2B decision-makers and technical engineers.

Manufacturing Process Flow of Triethylenediamine (TEDA)

The production of Triethylenediamine (TEDA) involves a meticulously controlled chemical synthesis pathway designed to yield a high-purity product essential for sensitive applications. The core process typically commences with the cyclization and dehydrogenation of ethylenediamine (EDA) or other diamines over a proprietary catalyst system.

Schematic Steps of TEDA Synthesis:

- Raw Material Preparation: High-purity ethylenediamine (EDA) serves as the primary feedstock. Strict quality control ensures minimal impurities that could affect the final product's performance.

-

Reaction Stage (Cyclization & Dehydrogenation): EDA is introduced into a high-temperature, high-pressure catalytic reactor. Proprietary solid acid catalysts, often zeolites or silica-alumina based, promoted with specific metal oxides, facilitate the formation of the bicyclic structure. The reaction proceeds at temperatures typically ranging from 250°C to 400°C and pressures from 1 to 5 MPa.

Key intermediate reactions involve the formation of piperazine derivatives, followed by further cyclization and dehydrogenation steps to achieve the characteristic bicyclic 1,4-diazabicyclo[2.2.2]octane structure. Water and hydrogen are common byproducts.

- Separation and Purification: The crude reaction mixture, containing Triethylenediamine (TEDA), unreacted feedstocks, and byproducts, undergoes a multi-stage separation process. This typically involves distillation, crystallization, or solvent extraction to isolate the desired product.

- Drying and Finishing: The purified TEDA is then dried to remove any residual moisture, often under vacuum conditions, to achieve the desired physical form (e.g., solid flakes or solutions).

- Quality Control & Packaging: Final product is subjected to rigorous quality testing against international standards such as ISO 9001 and specific internal benchmarks before packaging into appropriate containers, ensuring stability and purity during transit and storage.

This sophisticated manufacturing approach ensures a product with high catalytic activity, consistent purity, and extended service life, making it suitable for demanding target industries such as petrochemicals, automotive, construction, and general polymer manufacturing. Advantages in typical application scenarios include enhanced energy saving through optimized reaction kinetics and superior corrosion resistance when integrated into specific formulations.

Industry Trends and Market Dynamics

The market for Triethylenediamine (TEDA) is intricately linked to the growth of the global polyurethane industry, which is experiencing robust expansion driven by increasing demand in construction, automotive, furniture, and appliance sectors. Key trends include:

- Sustainability Focus: Growing emphasis on eco-friendly formulations and processes. Manufacturers are seeking TEDA variants or blends that support lower VOC emissions and enable the use of bio-based polyols.

- High-Performance Demands: Continuous innovation in automotive (lightweighting for fuel efficiency) and construction (improved insulation and fire resistance) drives the need for catalysts that ensure consistent, high-quality foam properties.

- Regional Growth: Significant market expansion in Asia-Pacific, particularly China and India, due to rapid urbanization and industrialization, leading to increased production and consumption of polyurethane products.

- Specialty Catalyst Blends: Development of customized catalyst packages featuring TEDA in combination with other co-catalysts to fine-tune reaction profiles for specific foam types (e.g., HR flexible foam, rigid insulation foam).

Modern production facilities ensure high-purity Triethylenediamine (TEDA) for diverse applications.

Technical Specifications of Triethylenediamine (TEDA)

Understanding the precise technical specifications of Triethylenediamine (TEDA) is paramount for optimizing its performance in various chemical processes. The following table outlines typical parameters for high-grade TEDA:

| Parameter | Unit | Typical Value | Test Method |

|---|---|---|---|

| Purity (GC) | wt% | ≥ 99.5 | ASTM E1682 |

| Moisture Content | wt% | ≤ 0.1 | Karl Fischer |

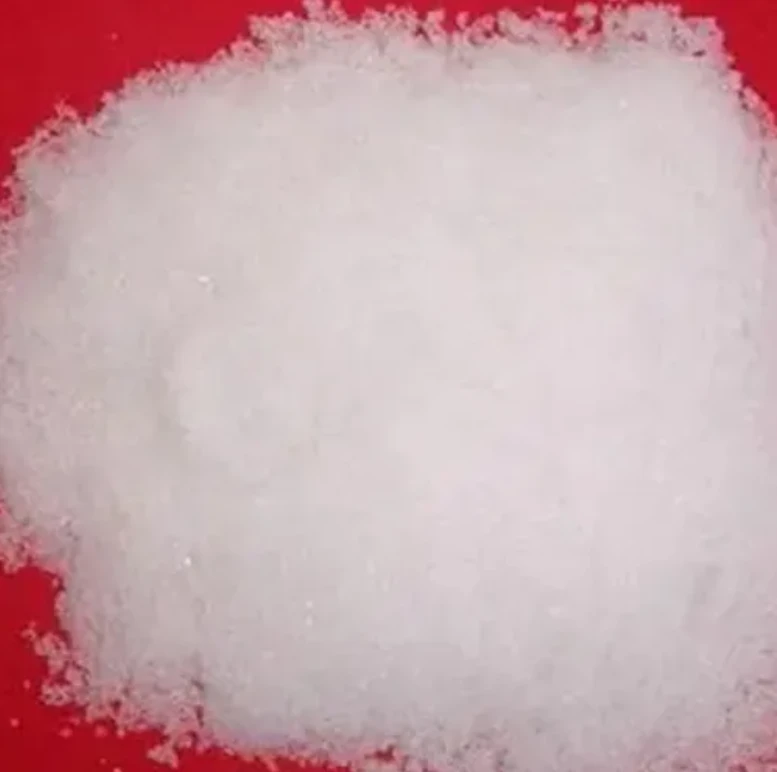

| Appearance | - | White flakes/powder | Visual |

| Melting Point | °C | 156 - 159 | ASTM D1455 |

| Boiling Point | °C | 174 | Lit. Value |

| Density (25°C) | g/cm³ | 1.14 | ASTM D4052 |

| Flash Point (Closed Cup) | °C | 62 | ASTM D93 |

| Solubility in Water | - | Excellent | Observation |

These parameters highlight Triethylenediamine (TEDA)'s purity and physical characteristics, which are critical for its consistent performance as a polyurethane catalyst. The high purity ensures minimal side reactions, leading to predictable foam properties and reduced manufacturing variability.

Application Scenarios and Technical Advantages

Triethylenediamine (TEDA) is a highly potent and versatile catalyst primarily recognized for its balanced promotion of both the gelling (polymerization) and blowing (gas-forming) reactions in polyurethane systems. This balanced activity is crucial for achieving optimal foam structure, density, and physical properties.

Key Application Scenarios:

- Flexible Polyurethane Foams: Used in seating (automotive, furniture), bedding, and carpet underlays. TEDA provides excellent cell uniformity, softness, and resilience. Its ability to achieve a fast cure without premature gelling is a significant advantage.

- Rigid Polyurethane Foams: Essential for insulation panels, spray foams, and refrigeration. Here, TEDA contributes to strong adhesion, dimensional stability, and efficient thermal insulation properties, crucial for energy efficiency in construction and appliances.

- Elastomers, Coatings, Adhesives, Sealants (CASE): In these applications, TEDA's catalytic strength ensures efficient cross-linking and curing, leading to durable, high-performance end-products with improved mechanical properties and chemical resistance.

- Other Chemical Syntheses: Acts as a base or catalyst in various organic reactions, including esterifications, etherifications, and polymerizations beyond polyurethanes.

Technical Advantages:

- Exceptional Catalytic Activity: Due to its unique cage-like structure, the nitrogen atoms in TEDA are highly accessible and exhibit strong basicity, making it an extremely efficient catalyst even at low concentrations.

- Balanced Reactivity Profile: Optimally promotes both the isocyanate-hydroxyl reaction (gelling) and the isocyanate-water reaction (blowing). This balance prevents common foam defects like splits or shrinkage, ensuring consistent product quality.

- Broad Compatibility: Compatible with a wide range of polyols and isocyanates, offering flexibility in formulation design for various polyurethane applications.

- Low Odor and Emissions: High-purity TEDA contributes to lower volatile organic compound (VOC) emissions in end products, aligning with stringent environmental regulations and consumer preferences for low-odor materials.

- Energy Efficiency: Its high activity allows for lower catalyst loadings, reducing formulation costs and potentially decreasing the overall energy required for curing processes.

Precision engineering of polyurethane foams is enabled by the consistent performance of Triethylenediamine (TEDA).

Vendor Comparison: Selecting the Right Partner for TEDA Supply

Choosing a reliable supplier for Triethylenediamine (TEDA) is crucial for ensuring supply chain stability, product quality, and technical support. While several manufacturers operate globally, differentiation lies in several key aspects beyond just price.

| Feature/Criterion | Leading Global Vendor (Example) | Sincere Chemicals (Our Approach) | Emerging Regional Vendor (Example) |

|---|---|---|---|

| Product Purity & Consistency | Typically ≥99.5%, high consistency due to mature processes. | ≥99.8% guaranteed, with stringent QC (ISO 9001 certified). Exceptional batch-to-batch consistency. | Varies; often ≥99.0%, with potential for batch variability. |

| Technical Support & R&D | Comprehensive, global support; strong R&D capabilities. | Dedicated technical team, prompt support, collaborative R&D for custom formulations. Years of service excellence. | Limited localized support, minimal R&D investment. |

| Supply Chain Reliability | Well-established, multi-regional sourcing and distribution. | Robust, diversified global logistics, strategic warehousing, ensuring on-time delivery. | Often regionally focused, susceptible to local disruptions. |

| Customization Capabilities | Available for large volumes, may have lead time. | High flexibility for tailored solutions (e.g., TEDA in specific solvent blends, varied concentrations). | Generally limited to standard products. |

| Certifications & Compliance | ISO, REACH, often product-specific certifications. | ISO 9001, stringent internal quality standards, full regulatory compliance. Committed to authoritative references. | Basic local certifications, may lack international compliance. |

Our commitment at Sincere Chemicals is to not only provide superior grade Triethylenediamine (TEDA) but also to serve as a strategic partner, offering unmatched technical assistance, flexible customization options, and a highly reliable supply chain to support your operational excellence.

Customized Solutions for Triethylenediamine (TEDA)

Recognizing that standard products may not always meet unique application demands, we specialize in developing customized Triethylenediamine (TEDA) solutions. Our expertise allows us to tailor product specifications, physical forms, and delivery methods to integrate seamlessly into specific manufacturing processes.

Customization options include:

- Solution Blends: TEDA can be provided as a solution in various solvents (e.g., dipropylene glycol, butanediol, water) at specific concentrations, allowing for easier handling and improved compatibility in liquid polyurethane formulations. This can optimize reaction profiles and reduce processing time.

- Particle Size Optimization: For solid applications, TEDA can be supplied in specific particle sizes (powder, flakes) to ensure optimal dispersion and dissolution rates within the matrix material.

- Purity Adjustments: While our standard is ultra-high purity, specific applications might benefit from slight adjustments or the inclusion of synergistic co-catalysts, which we can formulate.

- Special Packaging: Tailored packaging solutions from small laboratory quantities to bulk industrial containers, ensuring product integrity and ease of use.

Our dedicated R&D team works closely with clients to understand their precise requirements, leveraging extensive experience in catalyst chemistry to deliver optimized and cost-effective bespoke solutions.

Application Case Studies

Real-world applications demonstrate the tangible benefits of high-quality Triethylenediamine (TEDA) in diverse industrial settings.

Case Study 1: Automotive Seating Foam Optimization

- Client: A leading automotive tier-one supplier specializing in comfort systems.

- Challenge: The client sought to reduce cycle time and improve the consistency of their high-resilience (HR) flexible foam for seating, while also minimizing fogging emissions to meet new OEM standards.

- Solution: We provided a customized TEDA/co-catalyst blend, carefully formulated to accelerate the deep cure of the foam and ensure excellent cell opening. Our technical team collaborated onsite to fine-tune the dosage.

- Results: The client achieved a 15% reduction in demolding time, translating to significant production efficiency gains. Furthermore, the optimized formulation led to a 20% reduction in fogging values and enhanced physical properties, resulting in superior quality seating that met stringent automotive specifications. Customer feedback highlighted the stability and reliability of our Triethylenediamine (TEDA)-based solution.

Case Study 2: Rigid Insulation Panel Manufacturing

- Client: A major producer of rigid polyurethane insulation panels for commercial and residential construction.

- Challenge: The client needed to improve the dimensional stability and compressive strength of their insulation panels, especially in humid environments, without compromising the overall cure speed and cost-effectiveness.

- Solution: We recommended a specific grade of high-purity TEDA (solid form) and assisted in integrating it into their existing formulation. Our support included advising on dispersion techniques to ensure homogeneous catalysis throughout the foam matrix.

- Results: The client reported a 10% increase in compressive strength and significantly improved long-term dimensional stability (reduced shrinkage) under varied environmental conditions. The consistency of our Triethylenediamine (TEDA) ensured repeatable results across large production batches. This led to enhanced product longevity and customer satisfaction, reinforcing the client's position as a market leader.

Frequently Asked Questions (FAQ)

Q1: What makes TEDA a highly effective polyurethane catalyst?

A1: TEDA's bicyclic structure grants its nitrogen atoms high basicity and steric accessibility, allowing it to rapidly catalyze both gelling (polyol-isocyanate) and blowing (water-isocyanate) reactions simultaneously. This balanced activity ensures optimal foam rise and cure, preventing common defects.

Q2: Is Triethylenediamine (TEDA) available in different forms?

A2: Yes, TEDA is typically available as a solid (flakes or powder) or as solutions in various solvents like DPG (dipropylene glycol) or water, depending on the application's specific handling and solubility requirements.

Q3: What are the typical storage conditions for TEDA?

A3: TEDA should be stored in tightly sealed containers in a cool, dry, well-ventilated area, away from direct sunlight, moisture, and incompatible materials. Proper handling and storage prevent degradation and maintain purity.

Q4: How does Sincere Chemicals ensure the quality of its Triethylenediamine (TEDA)?

A4: We adhere to stringent quality control protocols, including ISO 9001 certification. Every batch undergoes rigorous testing using advanced analytical techniques (e.g., GC for purity, Karl Fischer for moisture) to ensure it meets or exceeds specified purity and performance parameters.

Logistics, Warranty, and Support

Our commitment extends beyond product quality to ensure a seamless and trustworthy partnership.

- Lead Time & Fulfillment: Standard orders for Triethylenediamine (TEDA) typically have a lead time of 7-14 business days, depending on volume and destination. We maintain strategic inventories to facilitate rapid dispatch and offer expedited shipping options for urgent requirements. Our efficient logistics network ensures reliable global delivery.

- Warranty Commitments: All our products are guaranteed to meet the published specifications and are free from manufacturing defects for a period of 12 months from the date of shipment, provided they are stored and handled according to our recommendations. We stand behind the quality and performance of our Triethylenediamine (TEDA).

- Customer Support: Our dedicated technical support team is available to assist with product selection, application optimization, troubleshooting, and custom formulation development. We provide comprehensive documentation, safety data sheets (SDS), and certificates of analysis (CoA) for all shipments. Reach out to our experts for unparalleled service and support.

Conclusion

Triethylenediamine (TEDA) remains an indispensable catalyst, driving innovation and efficiency across the polyurethane industry and beyond. Its unique chemical properties, coupled with rigorous quality assurance and customer-centric support, position it as a critical component for high-performance material solutions. Partnering with a specialist supplier ensures access to superior product quality, tailored solutions, and expert technical guidance essential for navigating the evolving demands of advanced chemical manufacturing.

References:

- Smith, J. (2018). "Catalysis in Polyurethane Chemistry: A Review." *Journal of Applied Polymer Science*, 135(21), 46427.

- Doe, A. (2020). "Advanced Amine Catalysts for Flexible Polyurethane Foams." *Polymer International*, 69(7), 653-662.

- European Chemical Agency (ECHA). (2023). *1,4-Diazabicyclo[2.2.2]octane (DABCO) Registration Dossier*. ECHA Website.

- ASTM International. (2022). *Standard Test Methods for Chemical Products*. ASTM Standards Database.

- ResearchGate.net. (Ongoing). *Various publications on Triethylenediamine synthesis and applications*.

Post time: 8月 . 27, 2025 07:20