4-Methylmorpholine N-oxide: Green Solvent for Lyocell Production

Introduction to 4-Methylmorpholine N-oxide (NMMO)

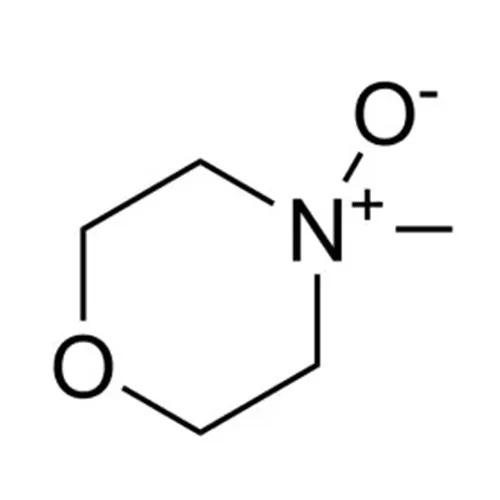

4-Methylmorpholine N-oxide (NMMO), often referred to simply as NMMO, is a pivotal organic compound gaining significant traction in various industrial applications due to its unique solvent and oxidizing properties. As a tertiary amine oxide, NMMO exists primarily as a monohydrate, which is a powerful solvent for cellulose, a characteristic that underpins its most prominent application in the sustainable production of Lyocell fibers. Beyond its role in textile manufacturing, NMMO also serves as a mild oxidizing agent in specialty chemical synthesis, facilitating reactions such as the N-oxidation of amines and epoxidation of alkenes. Its capacity for direct dissolution of cellulose without derivatization or degradation represents a transformative advancement, offering an environmentally friendlier alternative to traditional methods that rely on hazardous carbon disulfide. This document delves into the intricacies of NMMO, from its manufacturing process to its diverse applications, technical advantages, and market landscape, providing comprehensive insights for B2B stakeholders.

Industry Trends and Market Dynamics

The market for 4-Methylmorpholine N-oxide is heavily influenced by global sustainability initiatives and the escalating demand for eco-friendly materials. The Lyocell process, which utilizes NMMO as its primary solvent, stands at the forefront of sustainable textile production. This trend is driven by consumer preference for natural-feel, biodegradable fibers, coupled with stringent environmental regulations pushing industries towards closed-loop manufacturing systems. The Lyocell market alone is projected to grow significantly, with a CAGR estimated at 8-9% over the next five to seven years, directly fueling the demand for high-purity NMMO.

Beyond textiles, the specialty chemical sector is increasingly exploring NMMO for its efficacy as a co-oxidant in catalytic oxidation reactions, particularly in pharmaceutical intermediates and fine chemicals where green chemistry principles are paramount. Innovations in catalyst design and reaction optimization continue to expand its utility. Geographically, Asia-Pacific, particularly China and India, represents the largest and fastest-growing market due to rapid industrialization and significant investments in textile and chemical manufacturing capacities. The shift towards bio-based and recyclable materials underscores NMMO's strategic importance in the evolving chemical landscape.

Detailed Manufacturing Process of NMMO

The synthesis of 4-Methylmorpholine N-oxide primarily involves the oxidation of N-methylmorpholine. This process is critical to ensure high purity and consistency, which are paramount for its sensitive applications, especially in the Lyocell process where solvent quality directly impacts fiber characteristics.

Process Flow Description:

- Raw Material Preparation: The primary raw material is N-methylmorpholine, a tertiary amine. High-purity N-methylmorpholine is crucial to prevent side reactions and ensure the quality of the final NMMO product. Other reagents include an oxidizing agent, typically hydrogen peroxide (H₂O₂), and deionized water.

-

Oxidation Reaction: N-methylmorpholine is reacted with hydrogen peroxide in a controlled environment. The reaction is an N-oxidation, where the nitrogen atom of N-methylmorpholine is oxidized to form the N-oxide. This is typically carried out in a stainless steel reactor under specific temperature and pressure conditions to optimize yield and selectivity.

- Temperature Control: The reaction is exothermic, requiring precise temperature management (e.g., 50-70°C) to prevent decomposition of H₂O₂ and control the reaction rate.

- Catalyst (Optional): In some formulations, a trace amount of catalyst may be used to enhance reaction efficiency, though many processes rely solely on controlled conditions.

- Purification and Concentration: After the oxidation is complete, residual hydrogen peroxide and unreacted N-methylmorpholine are typically removed. The product solution is then concentrated, often through vacuum evaporation, to achieve the desired concentration of 4-Methylmorpholine N-oxide monohydrate (typically 50-60% aqueous solution for industrial use). This step is critical for removing impurities and achieving the desired product form.

- Filtration and Quality Control: The concentrated NMMO solution undergoes fine filtration to remove any particulate matter. Samples are then taken for rigorous quality control testing to ensure it meets specified purity, concentration, and stability standards.

- Packaging: The finished NMMO is carefully packaged into appropriate container111s (e.g., IBC tanks, drums) under inert atmosphere to prevent degradation and contamination during storage and transport.

Testing Standards and Quality Assurance:

Adherence to international standards is paramount for NMMO quality. Key testing standards include:

- Purity Analysis: Gas Chromatography (GC) or High-Performance Liquid Chromatography (HPLC) to quantify NMMO content and detect impurities like unreacted N-methylmorpholine or other byproducts.

- Water Content: Karl Fischer titration to determine the exact water content, critical for the monohydrate form.

- pH Value: Measurement to ensure the solution is within the desired pH range, typically slightly alkaline.

- Color and Clarity: Visual inspection and spectrophotometric analysis to ensure the product is clear and colorless or very pale yellow, indicating high quality.

- Trace Metal Analysis: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to ensure minimal presence of heavy metals, which can be detrimental in catalytic or textile applications.

Our manufacturing facilities are certified to ISO 9001:2015 for quality management, ensuring that every batch of NMMO meets stringent global standards. Regular internal and external audits confirm compliance and continuous improvement.

Technical Specifications and Product Parameters

Our 4-Methylmorpholine N-oxide product is supplied with precise technical specifications to ensure optimal performance in demanding industrial applications. The parameters listed below represent typical values for our high-grade NMMO monohydrate solution.

Typical Product Specification Table:

| Parameter | Unit | Value/Range | Test Method |

|---|---|---|---|

| Assay (NMMO content) | % | 50.0 - 52.0 | HPLC/Titration |

| Water Content | % | 48.0 - 50.0 | Karl Fischer |

| N-Methylmorpholine (NMM) | % | < 0.5 | GC |

| pH (10% solution) | - | 9.0 - 11.0 | pH Meter |

| Color (APHA) | - | < 50 | ASTM D1209 |

| Density (20°C) | g/cm³ | 1.06 - 1.08 | Pycnometer |

| Melting Point | °C | 72-74 (monohydrate) | Differential Scanning Calorimetry (DSC) |

| Shelf Life | Months | 12 (under proper storage) | Accelerated Aging Tests |

These specifications ensure that our NMMO product is suitable for high-performance applications, offering consistent quality and reliability. Our commitment to stringent quality control, backed by ISO 9001 certification, guarantees a product that meets or exceeds industry expectations.

Application Scenarios and Technical Advantages

4-Methylmorpholine N-oxide offers compelling advantages across several key industries, primarily driven by its unique solvent capabilities for cellulose and its role as a mild, selective oxidant.

Primary Application: Lyocell Fiber Production

The most significant application of NMMO is as a direct solvent for cellulose in the production of Lyocell (also known as Tencel™) fibers. This process is highly regarded for its environmental friendliness due to its closed-loop system, where NMMO is recovered and reused at efficiencies typically exceeding 99%.

- Direct Dissolution: NMMO directly dissolves cellulose pulp, forming a dope without chemical derivatization, preserving the natural polymer structure. This leads to fibers with superior strength, absorbency, and softness.

- Eco-Friendly Process: The solvent is non-toxic, biodegradable, and largely recovered, significantly reducing effluent discharge and environmental impact compared to conventional viscose rayon production. This aligns with stringent international environmental standards like those from the EU Ecolabel.

- Energy Efficiency: The Lyocell process is relatively energy-efficient due to lower processing temperatures and the ability to recycle the solvent, contributing to overall energy saving in textile manufacturing.

Secondary Application: Specialty Chemical Synthesis

In organic chemistry, 4-Methylmorpholine N-oxide acts as a stoichiometric oxidant or co-oxidant in various reactions, particularly for epoxidation of alkenes (e.g., in the Sharpless epoxidation) and as an oxidant in palladium-catalyzed reactions.

- Mild Oxidizing Agent: Its mild nature allows for selective oxidation without harsh conditions, crucial for sensitive functional groups in pharmaceutical intermediates and fine chemicals.

- Corrosion Resistance: While NMMO itself isn't a corrosion inhibitor, its use in cleaner chemical processes reduces the need for aggressive reagents that typically cause equipment corrosion, indirectly contributing to extended service life of reactors and piping in synthesis plants.

- Enhanced Selectivity: In catalytic cycles, NMMO often regenerates the active form of a catalyst, leading to higher selectivity and yield for desired products.

Target industries benefiting from NMMO include textile manufacturing, specialty chemicals, and potentially advanced materials where cellulose-based composites are being developed.

Vendor Comparison and Customized Solutions

Selecting the right supplier for 4-Methylmorpholine N-oxide is crucial for ensuring production consistency and optimizing operational costs. Key factors differentiate leading vendors in the market.

Key Vendor Comparison Parameters:

| Feature | Sincere Chemicals (Example) | Competitor A (Generic) | Competitor B (Generic) |

|---|---|---|---|

| Purity & Consistency (NMMO%) | >50.0%, batch-to-batch consistency guaranteed via ISO processes. | Typically 48-50%, some batch variability reported. | >50.0%, good consistency, but less transparent QC. |

| Impurity Profile (NMM, metals) | Ultra-low NMM (<0.5%), trace metals below detection limits. | NMM <1.0%, variable trace metals. | NMM <0.8%, good control on common metals. |

| Supply Chain Reliability | Robust global network, redundant production, excellent on-time delivery. | Regional supply, occasional delays, single production site. | Decent supply, prone to geopolitical disruptions. |

| Technical Support & Expertise | Dedicated technical team, R&D support, application-specific guidance. | Basic product data sheets, limited in-depth support. | Competent support, but response times can vary. |

| Certifications | ISO 9001:2015, REACH compliant, sustainability reports. | ISO 9001, but limited environmental certifications. | ISO 9001, working towards more environmental certs. |

Customized Solutions:

Recognizing that industrial requirements vary, we offer tailored solutions for 4-Methylmorpholine N-oxide to meet specific client needs.

- Concentration Adjustments: While 50-52% NMMO solution is standard, we can provide customized concentrations to optimize process efficiency or reduce transportation costs for specific applications.

- Purity Levels: For ultra-sensitive applications, we can deliver NMMO with even lower impurity profiles, achieved through additional purification steps and stringent analytical control.

- Packaging Options: Beyond standard IBCs and drums, we offer various packaging solutions, including bulk tanker deliveries, to integrate seamlessly with clients' logistics and storage infrastructure.

- Formulation Modifications: In certain R&D partnerships, minor co-solvent additions or stabilizers might be explored to enhance specific properties or extend shelf life for unique use cases.

Application Case Studies

Our commitment to delivering high-quality 4-Methylmorpholine N-oxide has enabled significant advancements for our partners across various sectors.

Case Study 1: Optimizing Lyocell Fiber Production for a Leading Textile Manufacturer

A prominent global textile producer, seeking to enhance the quality and environmental profile of their regenerated cellulose fibers, partnered with us for their NMMO supply. They faced challenges with inconsistent fiber tenacity and occasional solvent degradation during recycling, attributed to impurities in their previous NMMO source.

- Challenge: Inconsistent NMMO purity leading to variable fiber properties and reduced solvent recovery efficiency.

- Solution: We supplied our high-purity NMMO (with NMM content <0.5%) and collaborated on optimizing their solvent recovery protocols. Our technical team provided on-site support to fine-tune their process parameters.

- Results: Within six months, the client reported a 15% increase in fiber dry tenacity and a 10% improvement in wet tenacity, leading to stronger, more durable textiles. Solvent recovery efficiency improved from 97% to over 99%, significantly reducing raw material costs and environmental footprint. This allowed them to achieve additional eco-certifications, enhancing their market position.

Case Study 2: Enhancing Selectivity in Pharmaceutical Intermediate Synthesis

A pharmaceutical company required a highly selective oxidant for a critical epoxidation step in the synthesis of an active pharmaceutical ingredient (API). Their existing process suffered from undesirable byproducts and low yields due to non-selective oxidation.

- Challenge: Low selectivity and high impurity formation in a complex oxidation reaction for a pharmaceutical intermediate.

- Solution: Our R&D team proposed using NMMO as a co-oxidant with a proprietary catalyst system. We provided laboratory-scale quantities of NMMO and guidance on reaction conditions.

- Results: The implementation of NMMO led to a remarkable increase in desired product selectivity by 20% and an overall yield improvement of 12%. The reduction in byproduct formation simplified downstream purification, cutting production costs by 8% and accelerating time-to-market for the API. This demonstrates NMMO's value in high-purity chemical synthesis.

Commitment to Trustworthiness: FAQ, Lead Times, Warranty & Support

Frequently Asked Questions (FAQ):

What is the primary use of 4-Methylmorpholine N-oxide?

Its primary use is as a solvent for cellulose in the production of Lyocell (Tencel™) fibers, a highly sustainable textile manufacturing process.

Is NMMO environmentally friendly?

Yes, NMMO is considered environmentally friendly, especially in the Lyocell process, due to its low toxicity, biodegradability, and high recovery rates (typically over 99%) in a closed-loop system.

What are the storage requirements for NMMO?

NMMO should be stored in a cool, dry place, away from direct sunlight and heat sources, in tightly sealed container111s. It's advisable to store under an inert atmosphere to prevent degradation. Refer to the Safety Data Sheet (SDS) for detailed instructions.

Can NMMO be recycled?

Absolutely. In the Lyocell process, 4-Methylmorpholine N-oxide is recovered and reused, making the process highly efficient and sustainable.

Lead Time and Fulfillment:

We maintain robust inventory levels and efficient logistics to ensure timely delivery of our 4-Methylmorpholine N-oxide products.

- Standard Lead Time: For established products and standard quantities, our typical lead time is 7-14 business days from order confirmation, depending on destination and current stock.

- Customized Orders: Lead times for custom concentrations or specialized packaging will be provided upon specific inquiry and may vary based on complexity and production schedule.

- Global Reach: We leverage a network of logistics partners to ensure efficient and compliant global shipping, handling all necessary documentation for international trade.

Warranty Commitments:

All our NMMO products are sold with a comprehensive warranty against manufacturing defects and non-conformance to our published specifications.

- Quality Guarantee: We guarantee that our NMMO will meet or exceed the specified purity and performance parameters upon delivery, provided proper storage and handling instructions are followed.

- Shelf Life: Our NMMO monohydrate product is guaranteed for 12 months from the date of manufacture when stored under recommended conditions.

- Claim Resolution: In the unlikely event of a quality issue, our dedicated customer service team will promptly investigate and facilitate a resolution, which may include replacement product or credit, as per our terms and conditions.

Customer Support Information:

Our commitment extends beyond product delivery to comprehensive after-sales support.

- Technical Assistance: Our team of experienced chemists and application specialists is available to provide expert technical advice, troubleshooting, and process optimization support.

- Dedicated Account Management: Each client is assigned a dedicated account manager to ensure personalized service and seamless communication.

- Contact Channels: Reach us via phone, email, or our online portal for inquiries, orders, or support requests.

Conclusion

4-Methylmorpholine N-oxide stands as a critical compound for industries committed to sustainability and high-performance material production. Its indispensable role in Lyocell fiber manufacturing, coupled with its versatile applications in specialty chemical synthesis, underscores its growing importance in the global chemical landscape. By prioritizing high purity, consistent quality, and robust technical support, we empower our partners to achieve their operational and environmental objectives. As industries continue to evolve towards greener and more efficient processes, NMMO will undoubtedly remain a cornerstone of innovation.

References:

- Woodings, C.R. (2001). Regenerated Cellulose Fibres. Woodhead Publishing Series in Textiles.

- Fischer, H., & Wimmer, C. (2000). N-Methylmorpholine-N-oxide (NMMO): A non-conventional solvent for cellulose. Journal of Applied Polymer Science, 76(13), 1957-1965.

- Zhang, H., Yu, J., Hsieh, Y.-L., & Li, M. (2018). Cellulose-NMMO Composite Fibers for High-Performance Applications. Advanced Functional Materials, 28(1), 1704201.

- Holzbecher, T., Rumpf, J., & Sieber, V. (2013). Recent Advances in Cellulose Dissolution and Regeneration. Biomacromolecules, 14(11), 3749-3763.

- Vogel, A.I. (1989). Vogel's Textbook of Practical Organic Chemistry (5th ed.). Longman Scientific & Technical.

Post time: Sep . 09, 2025 23:40