NMM Morpholine: High Purity Catalyst & Solvent for Industry

Introduction to N-Methylmorpholine

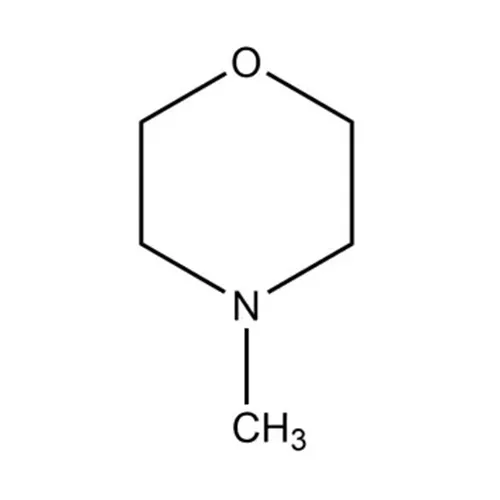

In the intricate landscape of specialty chemicals, NMM Morpholine stands as a pivotal organic compound with a broad spectrum of applications. Also known as N-Methylmorpholine, this heterocyclic amine is widely recognized for its excellent solvency, catalytic properties, and versatility in numerous industrial processes. From pharmaceutical synthesis to polyurethane catalysis, its unique chemical structure provides a critical advantage, facilitating efficient reactions and enhancing product performance. This comprehensive overview delves into the core aspects of NMM, examining its manufacturing, technical specifications, diverse applications, and the strategic advantages it offers to B2B stakeholders in highly demanding sectors.

Industry Trends and Market Dynamics

The market for specialty amines, including NMM Morpholine, is experiencing dynamic shifts driven by several key trends. Global demand for high-performance polymers, particularly polyurethanes, remains a significant growth driver. The automotive, construction, and insulation sectors continue to expand, directly impacting the consumption of NMM as a crucial catalyst. Furthermore, the pharmaceutical industry's continuous innovation in drug synthesis relies heavily on high-purity reagents like NMM for efficient reaction pathways.

Sustainability and environmental regulations are also shaping the market. Manufacturers are increasingly focused on green chemistry principles, seeking cleaner production processes and reduced solvent emissions. This has led to an emphasis on high-efficiency catalysts that minimize by-products and facilitate solvent recovery, where NMM's properties can be highly beneficial. Advancements in organic synthesis, coupled with increasing R&D investments in emerging economies, are expected to further bolster the market growth for NMM in the coming years. The demand for consistent quality and reliable supply chains also underscores the importance of reputable vendors in this specialized chemical segment.

Manufacturing Process Flow of N-Methylmorpholine

The production of NMM Morpholine involves a carefully controlled multi-step synthesis designed to yield a high-purity product suitable for demanding industrial applications. The primary raw material is typically morpholine, which undergoes a reductive methylation process.

Schematic Steps:

- Raw Material Sourcing & Pre-treatment: High-grade morpholine is procured and subjected to quality checks to ensure purity and absence of contaminants. Other essential reagents, such as formaldehyde solution (or paraformaldehyde) and formic acid (or hydrogen with a catalyst), are also verified.

- Reaction (Reductive Methylation): Morpholine is reacted with a methylating agent, typically formaldehyde, in the presence of a reducing agent such as formic acid (Leuckart reaction) or hydrogen over a catalyst (catalytic hydrogenation).

- Leuckart Reaction: Morpholine + Formaldehyde + Formic Acid → N-Methylmorpholine + CO₂ + H₂O. This is a common industrial route due to its simplicity and effectiveness.

- Catalytic Hydrogenation: Morpholine + Formaldehyde (or a methanol derivative) + H₂ (over Ni or Pt catalyst) → N-Methylmorpholine + H₂O. This method offers high selectivity and can be more environmentally friendly by avoiding formic acid by-products.

- Separation & Purification: Post-reaction, the crude product mixture undergoes a series of separation and purification steps. This often includes neutralization (if acidic by-products are present), distillation to remove unreacted raw materials, water, and lighter or heavier impurities. Advanced rectification columns are employed to achieve the desired purity level for NMM.

- Quality Control & Testing: Throughout the process, and especially post-purification, samples are rigorously tested. Key parameters include purity (typically >99.0% by GC), moisture content, color (APHA), and density. Testing standards adhere to international benchmarks such as ISO 9001 quality management systems.

- Packaging & Storage: The finished N-Methylmorpholine is then packaged into appropriate container111s (e.g., drums, IBCs, ISO tanks) under inert atmospheric conditions to prevent contamination and ensure product stability during transport and storage.

Our manufacturing processes are designed for optimal energy efficiency and minimal environmental impact, contributing to reduced operational costs and enhanced sustainability for our partners. This meticulous approach ensures a consistent supply of high-purity NMM with an extended service life in its target applications, which span petrochemicals, fine chemical synthesis, and specialized polymer industries, where advantages like enhanced reaction kinetics and superior solvent performance are paramount.

Technical Specifications and Properties

Understanding the precise technical specifications of NMM Morpholine is crucial for its effective deployment in various industrial applications. As a tertiary amine, it exhibits characteristic basicity, excellent solubility in water and most organic solvents, and a relatively low boiling point, making it an ideal choice for specific catalytic and solvent roles.

Key Physicochemical Properties:

- Chemical Formula: C₅H₁₁NO

- Molecular Weight: 101.15 g/mol

- CAS Number: 109-02-4

- Appearance: Clear, colorless liquid

- Odor: Amine-like

Product Specification Table: Sincere Chemicals NMM Morpholine (Typical Values)

| Parameter | Specification | Test Method |

|---|---|---|

| Purity (N-Methylmorpholine) | ≥ 99.5% | Gas Chromatography (GC) |

| Moisture Content | ≤ 0.1% | Karl Fischer |

| Color (APHA) | ≤ 20 | ASTM D1209 |

| Density (20°C) | 0.918 - 0.922 g/cm³ | ASTM D4052 |

| Boiling Point | 115 - 116 °C | Internal Method |

| Refractive Index (nD20) | 1.434 - 1.436 | ASTM D1218 |

These specifications highlight the premium quality and consistent performance of our NMM. The low moisture content and high purity are particularly critical for applications sensitive to water, such as polyurethane foam production and complex organic synthesis, ensuring optimal reaction outcomes and product stability.

Application Scenarios

The versatility of NMM Morpholine allows it to play a critical role across a multitude of industrial applications, driven by its unique chemical properties as a tertiary amine.

- Polyurethane Catalysis: NMM is a widely used co-catalyst in the production of polyurethane foams, elastomers, and coatings. It accelerates the isocyanate-hydroxyl reaction, influencing gel time, cure rate, and ultimately, the physical properties of the final polymer. Its moderate reactivity helps in achieving a balanced reaction profile, contributing to optimal foam cell structure and mechanical strength, thus enabling energy saving in processes by optimizing reaction conditions.

- Organic Synthesis & Pharmaceuticals: As a strong organic base, NMM is an invaluable reagent and solvent in various organic synthesis reactions. It is particularly effective as an acid scavenger in esterification, acylation, and halogenation reactions. In pharmaceutical manufacturing, it serves as a reaction intermediate for the synthesis of complex active pharmaceutical ingredients (APIs), ensuring high yields and purity of target molecules.

- Rubber Processing: NMM acts as a processing aid and accelerator in the rubber industry, especially for sulfur vulcanization. It helps to improve the cure rate and properties of natural and synthetic rubbers, enhancing their durability and performance.

- Corrosion Inhibitors: Due to its basic nature and film-forming capabilities, NMM finds application in some formulations for corrosion inhibition, particularly in boiler water treatment and oil and gas systems. It neutralizes acidic components and can form a protective layer on metal surfaces, significantly extending the service life of equipment and reducing maintenance costs, thereby demonstrating excellent corrosion resistance.

- Solvent Applications: NMM’s excellent solvency for a wide range of organic compounds makes it suitable as a solvent in specialized coatings, adhesives, and textile processing. Its ability to dissolve polar and non-polar substances efficiently contributes to uniform application and improved product quality.

Technical Advantages of Our N-Methylmorpholine

Our NMM Morpholine offers distinct technical advantages that set it apart in the market, directly contributing to superior performance and cost-efficiency for our industrial partners.

- Exceptional Purity: Achieved through stringent manufacturing processes and advanced distillation techniques, our NMM consistently boasts a purity level of >99.5%. This high purity minimizes side reactions, reduces catalyst loading, and ensures predictable, repeatable results in sensitive chemical syntheses and polymerizations.

- Optimal Catalytic Activity: The precise molecular structure and minimal impurity profile of our NMM guarantee optimal catalytic performance in polyurethane systems. This translates to efficient reaction kinetics, improved processing windows, and enhanced physical properties of the final product, such as superior insulation values for foam applications.

- Consistent Quality & Stability: We maintain rigorous quality control protocols, including ISO 9001 certification, to ensure every batch of NMM meets or exceeds industry standards. This consistency is vital for continuous production processes, reducing batch-to-batch variations and upholding product reliability over extended periods.

- Enhanced Safety Profile: Our NMM is produced and handled with strict adherence to safety guidelines, minimizing the presence of undesirable volatile compounds. This focus on product integrity contributes to safer handling and processing environments for our clients.

- Reliable Supply Chain: With years of dedicated service and established global logistics, we ensure a stable and timely supply of NMM, mitigating risks associated with supply disruptions and enabling seamless operations for our partners.

Our commitment to quality is reinforced by our ISO certifications and long-standing partnerships with leading chemical companies, underscoring our authority and expertise in the field.

Vendor Comparison: N-Methylmorpholine Suppliers

Choosing the right supplier for critical reagents like NMM Morpholine can significantly impact manufacturing efficiency, product quality, and cost-effectiveness. A comprehensive comparison reveals key differentiators beyond just price.

| Feature/Aspect | Sincere Chemicals NMM | Competitor A (Generic) | Competitor B (Economy) |

|---|---|---|---|

| Purity (NMM) | ≥ 99.5% (consistent) | 99.0% - 99.3% (variable) | 98.5% - 99.0% (lowest cost) |

| Moisture Content | ≤ 0.1% | ≤ 0.2% | ≤ 0.5% |

| Quality Certifications | ISO 9001, REACH compliant | Basic internal QC | Limited/No certifications |

| Technical Support | Dedicated, experienced team | Standard support | Minimal support |

| Supply Chain Reliability | Robust, global, on-time delivery | Regional, occasional delays | Opportunistic, inconsistent |

| Customization Options | Yes (packaging, formulation) | Limited | No |

This comparison illustrates why selecting a supplier with a strong emphasis on consistent quality, comprehensive technical support, and a reliable supply chain, such as Sincere Chemicals, provides a significant competitive advantage for businesses operating in critical chemical applications. The seemingly higher initial cost of a premium product is often offset by reduced waste, improved process efficiency, and superior end-product quality.

Customized Solutions

Recognizing that every industrial application has unique requirements, Sincere Chemicals is committed to providing tailored solutions for NMM Morpholine. Our expertise extends beyond standard product supply, encompassing a full spectrum of customization options designed to integrate seamlessly with your specific operational needs.

- Specialized Packaging: We offer a range of packaging options, from standard drums and IBCs to bulk ISO tank container111s, ensuring suitability for various scales of operation and transportation logistics. Custom fill weights and specialized container111 materials can be arranged to meet specific handling and storage protocols.

- Formulation Adjustments: For complex applications requiring precise property profiles, we can collaborate on minor formulation adjustments, such as co-blending with other specific solvents or additives, provided they meet safety and regulatory standards.

- Technical Consulting & R&D Support: Our team of experienced chemists and technical specialists is available for consultation to optimize the use of NMM in your existing processes or to assist in new product development. We offer insights into reaction mechanisms, compatibility, and process optimization to maximize efficiency and yield.

- Dedicated Supply Chain Management: For high-volume or critical applications, we can develop bespoke supply chain strategies, including buffer stock arrangements, just-in-time delivery, and optimized freight solutions to ensure uninterrupted supply.

Application Case Studies & Customer Experience

Our track record of successful applications and positive customer feedback underscores the reliability and effectiveness of our NMM Morpholine.

Case Study 1: Enhanced Polyurethane Foam Production

A leading insulation material manufacturer was experiencing inconsistencies in the cell structure and cure rates of their rigid polyurethane foams, leading to variable R-values. Upon switching to Sincere Chemicals' high-purity NMM, they observed a remarkable improvement. The consistent purity and optimized catalytic activity of our NMM enabled them to achieve a more uniform cell distribution, faster demolding times, and a 5% increase in insulation efficiency (R-value). This directly translated to a reduction in waste, improved throughput, and higher customer satisfaction for their end products. The client reported a significant boost in operational reliability and cost savings due to reduced rework.

Case Study 2: Pharmaceutical Synthesis Optimization

A pharmaceutical API producer struggled with moderate yields and complex purification steps when using a competitor's NMM as an acid scavenger in a crucial coupling reaction. After consulting with our technical team and integrating our NMM, they were able to streamline their process. The high purity of our NMM minimized impurity formation, reducing the need for extensive downstream purification. This resulted in a 10% increase in reaction yield and a 15% reduction in overall processing time, significantly impacting their production costs and time-to-market for a vital drug. The client lauded our product's consistency and the responsive technical support provided.

"The consistent quality of Sincere Chemicals' N-Methylmorpholine has been instrumental in optimizing our polyurethane production line. Their technical team's support was invaluable in fine-tuning our formulations, leading to better product performance and significant cost savings." - Head of R&D, Major Insulation Manufacturer.

Commitment to Quality & Trustworthiness ()

At Sincere Chemicals, our dedication to excellence and customer satisfaction is underpinned by a robust framework of quality assurance and reliable service.

Certifications and Authoritative Compliance:

- ISO 9001:2015 Certified: Our entire production and supply chain management system is certified to ISO 9001, ensuring consistent product quality and continuous improvement.

- REACH Compliant: Our NMM products fully comply with the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations for safe use and handling within the EU market and beyond.

- Extensive Industry Experience: With over two decades of experience in specialty chemical manufacturing, we have cultivated deep expertise and a reputation for reliability in serving diverse global industries.

Frequently Asked Questions (FAQ)

A1: NMM Morpholine should be stored in a cool, dry, well-ventilated area away from direct sunlight and incompatible materials. Containers should be tightly sealed to prevent moisture absorption and maintain product integrity. Specific details are provided in our Safety Data Sheet (SDS).

A2: Our standard lead time for most orders is 7-14 business days, depending on volume and destination. We maintain strategic inventory levels and have robust logistics partners to accommodate urgent requests and ensure timely delivery. Customized supply agreements can further optimize lead times for regular clients.

A3: We guarantee that our NMM will meet the specified technical parameters as outlined in our product data sheet and certificates of analysis. Any product found not to meet these specifications will be addressed promptly according to our quality assurance policy, including replacement or credit. Our commitment is to ensure your complete satisfaction with our product quality.

Lead Time & Fulfillment Details:

Our sophisticated supply chain management system is designed for efficiency and reliability. We leverage a global network of logistics partners to ensure prompt and secure delivery of NMM Morpholine worldwide. Real-time tracking and dedicated account management keep our clients informed at every stage of their order, from processing to final delivery.

Customer Support:

Sincere Chemicals prides itself on comprehensive after-sales support. Our technical support team, composed of seasoned chemical engineers and application specialists, is readily available to assist with product integration, troubleshooting, and optimization. We offer tailored technical guidance, access to detailed product documentation, and responsive issue resolution, ensuring our partners achieve maximum value from our NMM.

Conclusion

As a critical and versatile chemical, NMM Morpholine plays an indispensable role in a wide array of industrial applications, from enhancing the performance of polyurethanes to facilitating complex pharmaceutical syntheses. Our commitment to manufacturing high-purity NMM, coupled with stringent quality control, responsive technical support, and robust supply chain management, positions Sincere Chemicals as a trusted partner for businesses seeking reliable and high-performance chemical solutions. By prioritizing product excellence and comprehensive customer service, we empower our clients to achieve their operational goals and maintain a competitive edge in their respective markets.

References

- Smith, M. B., & March, J. (2007). March's Advanced Organic Chemistry: Reactions, Mechanisms, and Structure (6th ed.). John Wiley & Sons.

- Oertel, G. (1993). Polyurethane Handbook: Chemistry, Raw Materials, Processing, Application, Disposal (2nd ed.). Hanser Publishers.

- International Organization for Standardization. ISO 9001:2015 - Quality management systems - Requirements.

- European Chemicals Agency (ECHA). REACH Regulation (EC) No 1907/2006.

- National Center for Biotechnology Information. PubChem Compound Summary for CID 8000, N-Methylmorpholine. Retrieved from https://pubchem.ncbi.nlm.nih.gov/compound/N-Methylmorpholine

Post time: Sep . 10, 2025 12:20