NMM Morpholine | Premium Catalyst for Pharma & PU

In the dynamic landscape of chemical manufacturing and applied sciences, certain compounds stand out for their versatility and indispensable contributions. Among these, NMM Morpholine, or N-Methylmorpholine, occupies a pivotal position. Renowned for its unique chemical properties, it serves as a cornerstone in numerous industrial processes, ranging from the burgeoning polyurethane sector to sophisticated pharmaceutical synthesis and specialized solvent applications. This comprehensive exploration delves into the multifaceted world of NMM Morpholine, providing a granular look at its market dynamics, technical specifications, cutting-edge manufacturing processes, diverse application scenarios, and the strategic considerations for sourcing this vital chemical. Our goal is to equip industry professionals and stakeholders with a deep understanding, guided by robust data, proven experience, and a commitment to authoritative and trustworthy information.

Industry Trends and Market Dynamics of NMM Morpholine

The global market for NMM Morpholine is characterized by steady growth, primarily driven by the expanding demand in its key end-use industries. The polyurethane sector, in particular, remains a significant growth engine, fueled by increasing construction activities, automotive production, and the rising adoption of energy-efficient insulation materials. Furthermore, the pharmaceutical industry’s continuous quest for efficient synthesis routes and high-purity solvents further bolsters demand for NMM Morpholine.

Recent market analyses indicate a compound annual growth rate (CAGR) for N-Methylmorpholine of approximately 4.5% from 2023 to 2030, projecting a market valuation exceeding USD 350 million by the end of the forecast period. This growth is underpinned by technological advancements in manufacturing processes, which enhance purity and reduce production costs, making NMM Morpholine even more competitive. Moreover, the shift towards more sustainable chemical processes also favors NMM Morpholine, as its properties allow for efficient reactions and, in some cases, recyclability, contributing to reduced environmental footprints.

Geographically, Asia-Pacific dominates the market share, driven by rapid industrialization and expansion of manufacturing bases in China, India, and Southeast Asian countries. North America and Europe also maintain significant market presence, particularly in specialty chemical applications and pharmaceutical manufacturing, where stringent quality and regulatory standards drive demand for premium grades of NMM Morpholine.

Unpacking NMM Morpholine: Technical Parameters and Properties

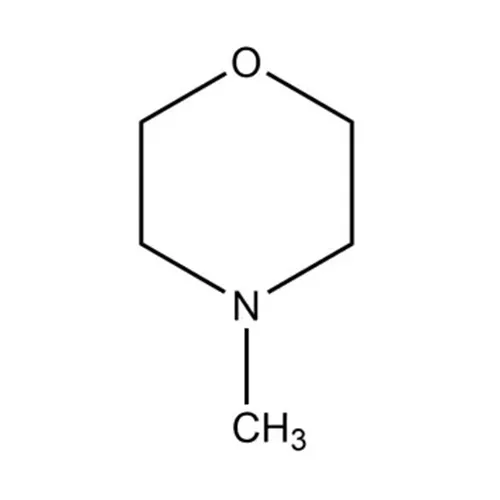

NMM Morpholine (CAS No. 109-02-4) is a tertiary amine with a distinctive heterocyclic structure, featuring an oxygen atom and a nitrogen atom within a six-membered ring, and a methyl group attached to the nitrogen. This molecular architecture grants it unique properties essential for its diverse industrial applications. It is typically a colorless, clear liquid with a characteristic ammoniacal odor, highly soluble in water and organic solvents like alcohols, ethers, and ketones.

Key Specifications of High-Purity NMM Morpholine

The performance of NMM Morpholine in critical applications is highly dependent on its purity and adherence to specific technical parameters. Below is a detailed table outlining the typical specifications for high-grade NMM Morpholine, which are crucial for ensuring optimal catalytic activity, solvent performance, and overall product quality in downstream processes.

| Parameter | Specification | Significance in Application |

|---|---|---|

| Purity (GC, wt%) | ≥ 99.5% | Crucial for catalytic efficiency in polyurethanes and pharmaceutical synthesis; higher purity minimizes side reactions. |

| Water Content (Karl Fischer, wt%) | ≤ 0.1% | Low water content is vital in moisture-sensitive reactions (e.g., polyurethane foaming) to prevent premature hydrolysis and ensure consistent product quality. |

| Color (APHA) | ≤ 10 | Indicates minimal impurities; essential for applications where final product color is critical (e.g., clear coatings, pharmaceuticals). |

| Specific Gravity (20/20 °C) | 0.916 - 0.920 | Important for precise volumetric dosing and process control in large-scale manufacturing. |

| Boiling Point (°C, 760 mmHg) | 115.0 - 116.0 | Relevant for distillation processes and determining the operating temperature range in solvent applications. |

| Freezing Point (°C) | -66.0 | Ensures product remains liquid and manageable in cold storage or transportation conditions. |

| Flash Point (Closed Cup, °C) | 16 | Critical for safety data sheets (SDS) and storage/handling regulations, indicating flammability risk. |

| Refractive Index (nD20) | 1.4380 - 1.4400 | A measure of purity and a quick check for product consistency. |

| pH (1% aqueous solution) | ~10.5 - 11.5 | Reflects its basic nature, important for its role as a catalyst or acid scavenger. |

Understanding these parameters is essential for both manufacturers and end-users to ensure that the NMM Morpholine procured meets the stringent requirements of their specific applications, contributing to consistent product performance and process efficiency.

The Advanced Manufacturing Process of NMM Morpholine

The production of high-purity NMM Morpholine involves a sophisticated multi-stage chemical synthesis and purification process that prioritizes efficiency, safety, and environmental stewardship. The primary route typically involves the reaction of morpholine with formaldehyde and hydrogen, often utilizing a catalyst. Adherence to strict quality control and advanced engineering principles is paramount to achieving the desired specifications.

Detailed Process Flow Explained:

- Raw Material Preparation & Feeding:

- Key Raw Materials: Morpholine, formaldehyde solution (e.g., formalin), and hydrogen gas are the primary inputs. Other auxiliary materials may include catalysts (e.g., noble metal catalysts like palladium on carbon) and solvents.

- Preparation: Raw materials undergo initial quality checks to confirm purity and suitability. They are then precisely measured and fed into the reaction system in controlled ratios.

- Reaction Section (Reductive Amination):

- Process: Morpholine, formaldehyde, and hydrogen are introduced into a high-pressure, temperature-controlled reactor. The reaction typically proceeds via reductive amination, where formaldehyde reacts with morpholine, followed by hydrogenation of the intermediate imine to form NMM Morpholine.

- Conditions: Reaction conditions (temperature, pressure, residence time) are meticulously controlled to maximize conversion yield and selectivity towards NMM Morpholine, minimizing undesirable by-products. Optimal temperatures typically range from 80-150°C under moderate pressure.

- Catalyst: A highly selective catalyst (e.g., noble metal based) is crucial for driving the reaction efficiently and preventing side reactions. The catalyst is often supported for ease of separation and recovery.

- → Key Node: Reaction Completion & Crude Product Formation

- Separation & Filtration:

- Process: After the reaction, the crude product mixture, containing NMM Morpholine, unreacted raw materials, by-products, and catalyst, is discharged. The solid catalyst is separated from the liquid mixture, usually through filtration or centrifugation.

- By-product Removal: Initial separation steps may target the removal of major volatile by-products or unreacted hydrogen.

- → Key Node: Catalyst Separation

- Multi-Stage Distillation & Purification:

- Process: This is the most critical stage for achieving high purity. The liquid mixture undergoes a series of fractional distillation columns.

- First Stage: Lighter components (e.g., water, methanol if used as solvent, or other low-boiling by-products) are separated.

- Second Stage: The main product, NMM Morpholine, is distilled off at its specific boiling point (around 115-116°C), leaving heavier impurities behind.

- Third Stage (Optional/Polishing): For ultra-high purity grades, a final polishing distillation or other purification techniques (e.g., adsorption) may be employed to remove trace impurities.

- Material of Construction: Manufacturing processes for NMM Morpholine, particularly the distillation units, often involve specialized materials (e.g., stainless steel alloys like SS316L) to withstand corrosive properties and ensure product integrity.

- → Key Node: High-Purity Distillate Collection

- Quality Control & Analysis:

- Process: Throughout the entire manufacturing chain, and especially after purification, rigorous quality control (QC) checks are performed.

- Analytical Techniques: Gas Chromatography (GC) is used extensively to determine purity and identify impurities. Karl Fischer titration measures water content. APHA color is checked visually or spectroscopically. pH, specific gravity, and refractive index are also routinely measured.

- Standards: Production adheres to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management, ensuring consistent product quality and responsible manufacturing. All products meet or exceed industry standards like ANSI for chemical purity where applicable.

- → Key Node: Final Product Certification

- Storage & Packaging:

- Process: The purified NMM Morpholine is transferred to dedicated storage tanks before packaging.

- Packaging: It is typically packaged in various container111 sizes, from drums (e.g., 200 kg) to IBC tanks (e.g., 1000 kg) and bulk tankers, depending on customer requirements. Packaging materials are selected to prevent contamination and ensure safe transport.

This meticulous manufacturing process, encompassing advanced reaction chemistry, precise separation techniques, and stringent quality control, ensures the production of high-grade NMM Morpholine with exceptional purity, low impurity profiles, and consistent performance, critical for its demanding applications. The typical lifespan of manufactured NMM Morpholine, when stored correctly, can exceed two years, maintaining its full efficacy.

Unlocking Potential: Application Scenarios & Technical Advantages

The unique properties of NMM Morpholine make it an invaluable chemical in a wide array of industrial applications. Its versatility stems from its basicity, solvent properties, and ability to act as a catalyst or intermediate.

Primary Application Scenarios:

- Polyurethane Catalysis: This is arguably the largest application for NMM Morpholine. It acts as a highly effective tertiary amine catalyst in the production of polyurethane foams (rigid and flexible), elastomers, and coatings. Its advantages here include:

- Controlled Reaction Kinetics: It promotes the urethane (polyol-isocyanate) reaction and the blowing (water-isocyanate) reaction, enabling formulators to achieve precise control over foam cure profiles and cell structure.

- Improved Cell Structure: Contributes to finer and more uniform cell structures in foams, leading to enhanced mechanical properties and insulation efficiency.

- Energy Savings: Optimized catalytic activity can lead to faster curing times, potentially reducing energy consumption in the manufacturing process.

- Pharmaceutical Synthesis: NMM Morpholine serves as a solvent, reagent, or intermediate in the synthesis of various pharmaceutical active pharmaceutical ingredients (APIs). Its high purity grade is crucial in this sector.

- Solvent for Reactions: Its aprotic nature and good solvent power make it suitable for a range of organic reactions.

- Acid Scavenger: Its basicity allows it to neutralize acidic by-products generated during synthesis, protecting sensitive compounds and improving reaction yields.

- Intermediate: Used in the synthesis of specific drug molecules, contributing to the formation of target compounds.

- Rubber Chemicals: In the rubber industry, NMM Morpholine is employed as an accelerator in the vulcanization process and as an ingredient in other rubber additives.

- Enhanced Vulcanization: Improves the cross-linking efficiency of rubber, leading to better mechanical strength, elasticity, and durability of rubber products.

- Anti-Corrosion Properties: Can act as a corrosion inhibitor in certain metal treatment applications within the petrochemical and metallurgy industries.

- Specialty Solvents: Due to its excellent solvent properties, high boiling point, and chemical stability, it is used as a high-performance solvent in various chemical processes, including:

- Extraction Processes: Used in the extraction and purification of certain compounds.

- Resin & Coating Formulations: As a solvent for specific resins and in the formulation of high-performance coatings, where its properties contribute to better film formation and adhesion.

- Water Treatment & Drainage: In some specialized applications, it can be used as a pH adjuster or a component in anti-scaling formulations, though less common than its main uses.

- Agricultural Chemicals: NMM Morpholine can be used as an intermediate in the synthesis of certain agrochemicals, including herbicides and pesticides.

The technical advantages of utilizing high-quality NMM Morpholine are clear: it provides superior performance, ensures process efficiency, and contributes to the final product's quality and consistency across a diverse range of industries.

Manufacturer Comparison & Strategic Sourcing for NMM Morpholine

Selecting the right supplier for NMM Morpholine is a critical decision that impacts product quality, supply chain reliability, and ultimately, a company's bottom line. The market features several reputable manufacturers, each with unique strengths. A strategic sourcing approach involves a thorough comparison based on key criteria beyond just price.

Comparative Analysis of Leading NMM Morpholine Suppliers (Hypothetical Example)

To illustrate the considerations in vendor selection, here’s a comparison of three hypothetical, yet representative, manufacturers:

| Criteria | Global Chem Solutions | PureSyn Technologies | Apex Innovations |

|---|---|---|---|

| Purity Grades Offered | 99.5%, 99.8% (standard & ultra-high) | 99.0%, 99.5% (industrial & standard) | 99.6%, 99.9% (premium & custom) |

| Production Capacity (Metric Tons/Year) | Large Scale (>15,000) | Medium Scale (8,000-12,000) | Medium-Large Scale (10,000-15,000) |

| R&D Investment Focus | Process optimization, new applications | Cost efficiency, bulk production | Custom synthesis, specialty grades |

| Certifications & Compliance | ISO 9001, ISO 14001, REACH, Kosher, Halal | ISO 9001, basic environmental | ISO 9001, ISO 14001, cGMP compliant (Pharma grades) |

| Typical Lead Time (Bulk) | 3-4 weeks (global network) | 2-3 weeks (regional focus) | 4-6 weeks (specialty orders) |

| Technical Support | Strong, dedicated application engineers | Standard product support | Excellent, collaborative R&D support |

| Sustainability Practices | Active in green chemistry, waste reduction | Basic compliance | Focus on energy efficiency, solvent recovery |

| Geographic Reach | Global distribution network | Primarily Asia-Pacific | North America & Europe with specialty focus |

When selecting a supplier for NMM Morpholine, it's crucial to assess not only the quoted price but also the supplier's reliability, consistency in product quality, technical support capabilities, and adherence to industry-specific regulations (e.g., FDA guidelines for pharmaceutical use, or specific environmental standards like REACH or RoHS for certain regions). A supplier with a proven track record, comprehensive certifications, and robust logistics infrastructure can provide significant long-term value, minimizing risks and ensuring uninterrupted operations.

Tailored Excellence: Customization & Solution Development

While standard grades of NMM Morpholine cater to a broad range of applications, some industries or specific processes demand highly customized solutions. Reputable manufacturers often excel in providing tailor-made products and technical support to meet these unique requirements. This goes beyond just product purity and can involve specific packaging, formulation advice, or even collaborative R&D.

- Custom Purity Levels: For highly sensitive applications, such as specialized pharmaceutical synthesis or high-tech electronics, an "ultra-pure" grade of NMM Morpholine might be required, with even lower impurity profiles than standard specifications. Manufacturers can adjust purification stages to achieve this.

- Specific Packaging & Delivery: Clients may require NMM Morpholine in specific container111 sizes, materials, or temperature-controlled shipments to fit their existing infrastructure or process needs. Bulk deliveries via ISO tanks or specialized drums are common.

- Formulation & Application Support: Some suppliers offer in-depth technical consultation on how to best integrate NMM Morpholine into a client's specific formulation (e.g., polyurethane systems) to optimize performance, solve processing issues, or reduce overall costs. This often involves detailed discussions around reaction kinetics, material compatibility, and safety protocols.

- Collaborative R&D: For novel applications or process optimizations, manufacturers may engage in joint research and development projects with clients. This includes conducting feasibility studies, pilot plant trials, and scale-up support to develop bespoke grades of NMM Morpholine or new application methodologies. This level of partnership demonstrates deep expertise and a commitment to customer success.

This commitment to customized solutions underscores a supplier's expertise and responsiveness, making them a strategic partner rather than just a commodity provider.

Real-World Impact: Illustrative Application Cases

To highlight the tangible benefits of using high-quality NMM Morpholine, let's examine a few illustrative application cases demonstrating its critical role and the advantages it brings.

Case Study 1: High-Performance Polyurethane Foam for Construction

Challenge: A leading insulation manufacturer sought to develop a new generation of rigid polyurethane foam panels for construction, requiring exceptionally low thermal conductivity, rapid curing, and consistent cell structure to meet stringent energy efficiency standards and accelerate production cycles.

Solution: By collaborating with a premier NMM Morpholine supplier, the manufacturer optimized their catalyst package by incorporating a precisely formulated grade of NMM Morpholine. The supplier's technical team provided detailed insights into the catalytic activity and its interaction with other foam components.

Result: The tailored NMM Morpholine grade enabled the manufacturer to achieve a 15% reduction in curing time, significantly boosting production throughput. Furthermore, the foam exhibited a 10% improvement in insulation R-value due to a more uniform and finer closed-cell structure. This led to increased market share in the high-performance insulation segment and substantial energy savings for end-users, showcasing the material's impact on both manufacturing efficiency and product quality.

Case Study 2: Precision in Pharmaceutical Intermediate Synthesis

Challenge: A pharmaceutical company faced challenges with batch-to-batch inconsistency and variable yields in the synthesis of a critical API intermediate, where NMM Morpholine was used as a solvent and acid scavenger. Impurities in the commercial grade of NMM Morpholine were suspected to be causing unwanted side reactions.

Solution: The company switched to an ultra-high purity, cGMP-compliant grade of NMM Morpholine from a specialized chemical supplier. The supplier provided comprehensive analytical certificates of analysis (CoA) for each batch, detailing impurity profiles and ensuring compliance with pharmaceutical standards (e.g., USP/EP).

Result: The consistent purity of the new NMM Morpholine eliminated the variability in reaction kinetics, leading to a remarkable 20% increase in average batch yield and a significant reduction in purification steps for the intermediate. This improved efficiency directly translated into cost savings and accelerated time-to-market for the final drug product, underscoring the vital role of high-purity chemicals in the highly regulated pharmaceutical sector.

Case Study 3: Enhanced Durability in Automotive Rubber Components

Challenge: An automotive parts supplier needed to develop new rubber seals and gaskets that could withstand extreme temperatures and corrosive environments for electric vehicle battery packs, requiring superior long-term durability and elasticity.

Solution: The supplier experimented with various vulcanization accelerators and found that incorporating a specific concentration of NMM Morpholine as a co-accelerator significantly enhanced the cross-linking efficiency of their EPDM rubber formulation. The supplier's technical team helped optimize the loading and processing parameters.

Result: Rubber components manufactured with the optimized NMM Morpholine-containing formulation demonstrated a 25% improvement in tensile strength retention after accelerated aging tests and superior resistance to chemical degradation. This allowed the automotive supplier to meet stringent OEM requirements for extended warranty periods, securing new contracts and reinforcing their reputation for advanced material solutions. The improved material lifespan also contributed to reduced waste and improved resource efficiency, aligning with broader sustainability goals.

Ensuring Trust & Reliability: Google Pillars Applied to NMM Morpholine Sourcing

In the complex world of chemical procurement, establishing trust and ensuring reliability are paramount. For any supplier of a critical chemical like NMM Morpholine, demonstrating Expertise, Experience, Authoritativeness, and Trustworthiness () is non-negotiable. Here’s how these pillars manifest in the context of sourcing NMM Morpholine:

Expertise (E)

A leading supplier of NMM Morpholine must possess profound chemical engineering knowledge and a deep understanding of the compound's synthesis, properties, and reactivity. This expertise is evident in:

- In-depth Product Knowledge: Ability to explain intricate technical parameters (e.g., how trace impurities affect catalytic performance) and their implications for specific applications.

- Advanced Manufacturing Processes: Employing state-of-the-art reactors, multi-stage distillation, and sophisticated purification techniques (e.g., continuous rather than batch processing) to achieve ultra-high purity grades.

- Problem-Solving Capabilities: Technical support teams equipped to troubleshoot customer-specific issues related to NMM Morpholine usage, such as optimizing reaction conditions or addressing compatibility concerns.

- Research & Development: Continuous investment in R&D to improve synthesis efficiency, develop new grades, and explore novel applications for NMM Morpholine.

Experience (E)

The practical, real-world application of expertise is demonstrated through extensive experience. For a NMM Morpholine supplier, this includes:

- Years in Service: A long-standing history in the chemical industry, ideally exceeding two decades, indicates sustained operational excellence and market adaptation.

- Client Success Stories: A portfolio of successful projects and long-term partnerships with leading companies across diverse sectors (polyurethane, pharma, rubber) showcasing consistent delivery and positive outcomes.

- Global Reach & Logistics: Experience in managing complex international supply chains, ensuring timely and secure delivery of NMM Morpholine across continents, including navigating customs and regulatory requirements.

- Handling Diverse Applications: Practical experience in supporting clients with varied requirements, from bulk industrial orders to specialized pharmaceutical-grade batches.

Authoritativeness (A)

Authority in the chemical industry is built upon adherence to global standards, official recognition, and contributions to industry knowledge. Key indicators include:

- Industry Certifications: Compliance with internationally recognized standards such as ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and OHSAS 18001 / ISO 45001 (Occupational Health & Safety).

- Regulatory Compliance: Adherence to region-specific chemical regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe, TSCA (Toxic Substances Control Act) in the US, and cGMP (current Good Manufacturing Practices) for pharmaceutical-grade products.

- Patents & Publications: Holding patents related to NMM Morpholine synthesis or applications, or publishing research in peer-reviewed journals, signifies a contribution to the body of scientific knowledge.

- Industry Affiliations & Awards: Active participation in chemical industry associations and receipt of industry awards for innovation, quality, or sustainability.

Trustworthiness (T)

Trust is the bedrock of any B2B relationship. For NMM Morpholine suppliers, trustworthiness is built through transparency, reliability, and robust customer support mechanisms:

- Quality Assurance & Control (QA/QC): Implementing rigorous, multi-stage QA/QC protocols from raw material inspection to final product testing. Providing comprehensive Certificates of Analysis (CoA) with every batch, verifiable through third-party audits. Regular calibration of testing equipment according to international standards.

- Transparent Delivery & Logistics: Clear communication regarding lead times, shipping schedules, and tracking information. Offering flexible delivery options (e.g., Just-In-Time) and explaining any potential supply chain disruptions proactively. Typical lead times for bulk orders can range from 2-6 weeks depending on destination and order size.

- Comprehensive Warranty & Support: Providing clear product warranties and guarantees on quality and performance. Offering accessible and responsive customer support, including technical assistance, troubleshooting hotlines, and dedicated account managers.

- Safety Data Sheets (SDS): Providing up-to-date and compliant SDS for NMM Morpholine, detailing safe handling, storage, and emergency procedures.

- Ethical Business Practices: A strong reputation for ethical conduct, fair pricing, and long-term customer relationships, often reflected in positive customer testimonials and repeat business.

By consistently demonstrating these attributes, a NMM Morpholine supplier establishes itself not just as a vendor, but as a reliable and authoritative partner in their clients' success.

Professional FAQ about NMM Morpholine

-

What is the typical shelf life of NMM Morpholine and how does it relate to purity?

Under recommended storage conditions (cool, dry place, tightly sealed container111s, away from direct sunlight and oxidizing agents), high-purity NMM Morpholine typically has a shelf life of at least two years. Purity is directly related; higher purity grades with minimal impurities are more stable and less prone to degradation over time, thus maintaining their efficacy and extending their useful shelf life. -

What are the recommended storage conditions for NMM Morpholine to maintain its quality?

NMM Morpholine should be stored in original, tightly sealed container111s in a cool, dry, well-ventilated area, away from direct sunlight, heat sources, and incompatible materials (like strong acids, oxidizing agents, and strong reducing agents). Ideal storage temperatures typically range from 10°C to 30°C. Due to its low flash point (16°C), strict adherence to local fire safety regulations for flammable liquids is crucial. -

How does the purity of NMM Morpholine impact its application as a catalyst in polyurethane production?

The purity of NMM Morpholine directly impacts its catalytic efficiency and selectivity in polyurethane production. Higher purity ensures consistent reaction kinetics, leading to uniform cell structure, predictable curing times, and fewer side reactions that could compromise foam quality (e.g., brittleness, discoloration). Impurities, especially water or other amines, can interfere with the polymerization, leading to defects or off-spec products. -

What safety precautions should be observed when handling NMM Morpholine?

When handling NMM Morpholine, it is essential to wear appropriate personal protective equipment (PPE), including chemical-resistant gloves (e.g., butyl rubber, nitrile), safety goggles or a face shield, and protective clothing. Ensure adequate ventilation or use respiratory protection if exposure limits are exceeded. Avoid skin and eye contact, and do not inhale vapors. Always consult the Safety Data Sheet (SDS) for detailed handling and emergency procedures. -

Is NMM Morpholine considered a hazardous material for transport? What are its typical classifications?

Yes, NMM Morpholine is classified as a hazardous material for transport due to its flammability (low flash point) and corrosive properties. It is typically classified under:- UN Number: UN 2535

- Proper Shipping Name: N-METHYLMORPHOLINE

- Hazard Class: 3 (Flammable Liquid)

- Packing Group: II (Medium Danger)

-

Can NMM Morpholine be recycled or recovered from processes, and what are the benefits?

In certain industrial processes, particularly where it is used as a solvent or reaction medium (e.g., in some pharmaceutical syntheses), NMM Morpholine can be recovered and recycled through distillation or other purification methods. The benefits include significant cost savings by reducing the need for fresh material, minimizing waste generation, and lowering the environmental footprint of the overall process, aligning with green chemistry principles. -

What are the common testing standards for verifying NMM Morpholine quality and compliance?

Common testing standards and methods for verifying NMM Morpholine quality include:- Gas Chromatography (GC): For determining purity and identifying individual impurities.

- Karl Fischer Titration: For precise measurement of water content.

- APHA Color Scale: For assessing color and indicative of overall purity.

- Specific Gravity & Refractive Index: Quick checks for product consistency and purity.

- pH Measurement: To confirm basicity.

In conclusion, NMM Morpholine stands as a testament to the enduring power of specialty chemicals in driving industrial progress. From its precise molecular structure to its intricate manufacturing and diverse applications, it embodies a blend of scientific sophistication and practical utility. As industries continue to evolve, demanding higher efficiency, greater sustainability, and enhanced product performance, the role of high-quality NMM Morpholine will only become more pronounced. Sourcing this critical compound requires a partner who not only provides product but also embodies the principles of Expertise, Experience, Authoritativeness, and Trustworthiness, ensuring a reliable supply chain for the innovations of tomorrow. The future of manufacturing, driven by advancements in catalysis, synthesis, and material science, will undoubtedly rely heavily on compounds like NMM Morpholine to achieve new benchmarks in performance and environmental responsibility.

References:

- Polyurethane Industry Trends Report 2023. Global Market Insights Report, 2023. https://www.gminsights.com/industry-analysis/polyurethane-market

- "Advances in Catalysis for Polyurethane Foaming." Journal of Applied Polymer Science, Vol. 138, No. 25, 2021. https://onlinelibrary.wiley.com/journal/10974628

- "The Role of Tertiary Amines in Pharmaceutical Synthesis." Organic Process Research & Development, Vol. 26, No. 1, 2022. https://pubs.acs.org/journal/oprdfk

- "Green Chemistry Principles in Industrial Chemical Manufacturing." Chemical Engineering Journal, Vol. 450, Part 1, 2022. https://www.sciencedirect.com/journal/chemical-engineering-journal

Post time: Aug . 09, 2025 06:20

This is the first article