bis 2 chloroisopropyl ether_o diaminobenzene

bis 2 chloroethyl ether

Bis(2-chloroethyl) ether (BCEE) is a specialized chemical compound predominantly used in the industr...

types of iodine

Iodine is an essential mineral playing a vital role in thyroid function, which, in turn, impacts met...

Phenyl Dichlorophosphate_ Applications in Organic Synthesis and Phosphorylation Reactions

Phenyl dichlorophosphate (C₆H₅OPOCl₂) is a halogenated organophosphate compound of significant indus...

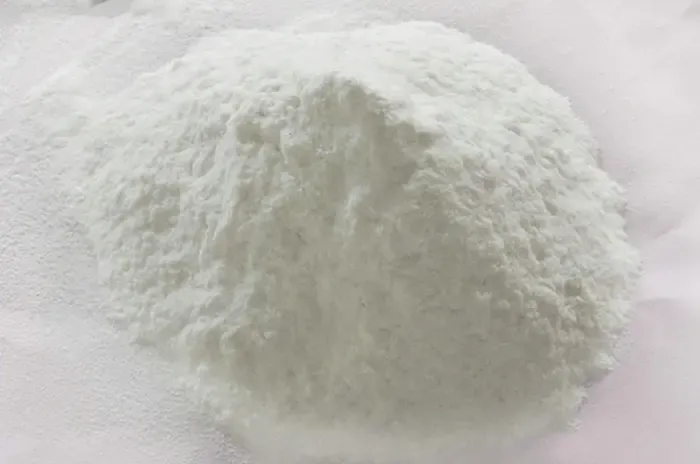

carboxy methyl cellulose sodium salt

Carboxy methyl cellulose sodium salt, commonly known as sodium CMC, is an incredibly versatile compo...

The future of sodium carboxymethyl cellulose manufacturing lies in an unwavering commitment to innovation and sustainability. As new applications emerge, especially in bioplastics and pharmaceuticals, factories that invest in continuous research and development will lead the charge. Integration of digital twins and AI-based quality controls can revolutionize production efficiency, setting new benchmarks for quality and reliability.

...

Links

- dichlorophosphate

- potassium iodide 30 mg

- sodium iodide i 123

- potassium iodide pills buy

- iodium tablet

- 1 3 propane diamine

- tetramethylethylenediamine cas no

- potassium iodide for nuclear attack

- n tallow 1 3 diaminopropane

- 5 iodine

- iodine oil

- potassium iodide dosage for nuclear attack

- diethyl formamide

- potassium iodide pharma

- potassium iodate liquid

- methylformamide

- iodine potassium iodide

- sodium iodide solid

- potassium iodide tablets price

- colorless iodine

- types of iodine

- potassium iodide after nuclear disaster

- carboxy cellulose

- carboxymethyl cellulose uses in food

- molecular iodine supplement

- n − methylpiperidine

- c8h15nao8

- iodide de potassium

- cas no 95 54 5

- iodine and potassium iodide

- kalium iodate

- potassium iodide for skin

- ki potassium iodide pills

- cyclopropyl methyl ketone

- iodine 130 mg

- potassium iodide emergency

- sodium carboxy

- 4 methylmorpholine

- iodine supplement for thyroid

- para diaminobenzene

- potassium iodide suppliers

- chlorella iodine

- n cyclohexyl n methylcyclohexanamine

- potassium iodide pills for nuclear

- potassium iodide 1kg

- potassium iodide 130 mg

- kegunaan potassium iodide

- formamide cas 75 12 7

- iodine products

- iodine as potassium iodide in supplements

- povidone iod

- potassium iodate bulk

- carboxymethylcellulose natrium

- formyl morpholine

- potassium iodide tablets buy

- white iodine

- sea moss iodine

- buy potassium iodate

- over the counter potassium iodide

- pharmaceutical potassium iodide

- use of povidone iodine solution

- nnn n tetramethylethylenediamine

- potassium iodide 250 mg

- potassium iodide pills over the counter

- hexamethylphosphoric triamide

- radblock potassium iodide

- potassium iodide for

- potassium iodide 135 mg

- cas 7681-55-2

- iodine edge

- cui copper iodide

- iodine for weight loss

- radiation pills potassium iodide

- purchase potassium iodide

- iodine

- 280 57 9 cas

- potassium iodide de

- potassium iodide in case of nuclear attack

- potassium iodide liquid for sale

- potassium iodide for

- iodine potassium iodide

- iodine for burns

- iodine plus potassium iodide

- 2 chloroethyl ether

- potassium iodide emergency

- hi hydroiodic acid

- 7681-55-2