dimetil formamide_dimetil formamide

liquid iodine supplement

As an essential mineral, iodine plays a crucial role in the synthesis of thyroid hormones, which are...

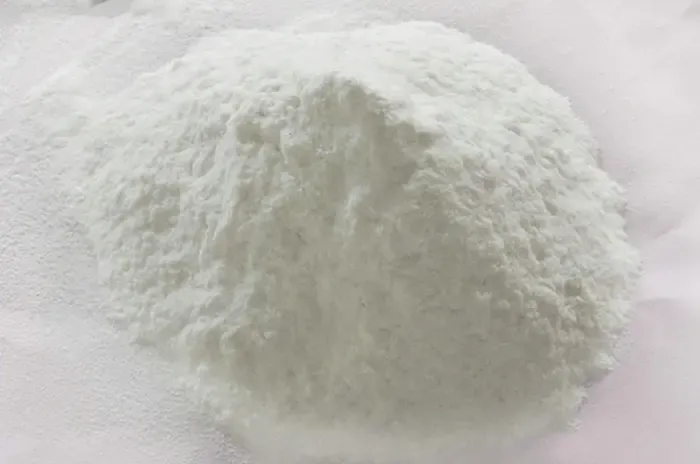

pure iodine

Pure iodine, a remarkable chemical element, has garnered significant attention across various indust...

phenyl dichlorophosphate cas no

Phenyl dichlorophosphate (CAS No . 770-12-7) is an important chemical in the realm of organic synthe...

N Methylformamide_ A Key Compound in Industrial Chemistry

N Methylformamide is a chemical compound that plays a significant role in various industrial and che...

7529 22 8

Navigating the vast landscape of product marketing requires a unique blend of experience, expertise,...

Links

- cas 7681-11-0

- copper 2 iodide

- potassium iodide pills over the counter

- iosol iodine

- potassium iodide drops for eyes

- methylpiperidine

- potassium iodide for radiation

- 4 methylmorpholine n oxide monohydrate

- potassium iodide anti radiation pill

- potassium iodide liquid for radiation

- sodium periodate price

- potassium iodide for

- nuclear attack potassium iodide

- formamide function

- sodium iodide suppliers

- morpholine n oxide

- potassium iodide antiseptic

- iodine over the counter

- cellulose sodium

- iodine 130 mg

- performance supplements potassium iodide

- le formamide

- potassium iodide sodium iodide

- potassium iodide nhs

- cas 7529 22 8

- ammonium iodide uses

- cmc cellulose

- n methylformamide china

- potassium iodide function

- natural iodine supplement

- catarlent potassium iodide harga

- potassium iodide crystal

- sodium iodide use

- potassium iodide pret

- potassium iodide drops for radiation

- tetra methyl piperidine

- povidone iodine

- iodide potassium pills

- sodium iodide salt

- potassium iodide ki pill

- what is formamide used for

- hydrogen iodide

- potassium iodide how to take

- iodium tablet

- vegan iodine

- potassium iodide ki pills for sale

- potassium iodide pills 130 mg

- buy potassium iodide pills

- cas 7758-05-6

- potassium iodide 125 mg

- potassium iodate potassium iodide

- sodium iodide water

- potassium iodide anti radiation

- i2 solution

- sodium carboxymethyl cellulose function

- sea kelp iodine

- tetra methyl ammonium iodide

- purchase potassium iodide

- pure hydroiodic acid

- hydriodic acid cas

- tetraethyl ammonium iodide

- prophylactic potassium iodide

- tetrabutylammonium iodide

- potassium iodide pills for radiation exposure

- cas 765 43 5

- potassium iodide supplements

- potassium iodide tincture

- iodine video

- iodine for nuclear exposure

- jual potassium iodide

- meta diaminobenzene

- hypothyroidism and potassium iodide

- n methylmorpholine cas

- povidone iodine for wounds

- iodine pdf

- iodine for hair growth

- iodate de sodium

- 2 iodine

- iodine 125

- potassium iodide in case of nuclear attack

- potassium iodide liquid for sale

- potassium iodide for

- iodine potassium iodide

- iodine for burns

- iodine plus potassium iodide

- 2 chloroethyl ether

- potassium iodide emergency

- hi hydroiodic acid

- 7681-55-2