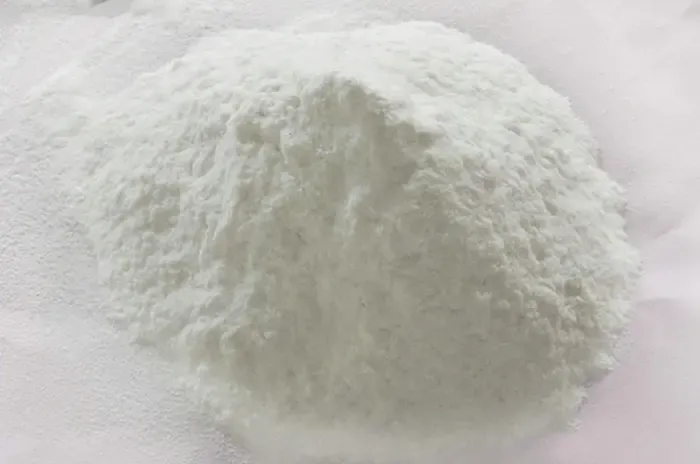

sodium carboxymethyl cellulose factory

Authoritativeness in the sodium CMC manufacturing domain stems not only from technical prowess but also from compliance with stringent global standards. Certifications such as ISO 22000 for food safety management systems and compliance with Good Manufacturing Practices (GMP) bolster a factory's reputation. These certifications are more than just accolades; they are a testament to the factory's commitment to quality, safety, and environmental responsibility. In building trustworthiness, transparency stands paramount. Open communication channels with clients and stakeholders about sourcing practices, environmental impacts, and quality audits cultivate confidence. Regular third-party audits and quality assessments serve as trust signals, reassuring clients about the product’s reliability and safety for consumption. Engagement in sustainability practices, such as waste minimization and energy-efficient technologies, further enhances a factory’s trustworthiness in a global market increasingly sensitive to environmental concerns. The future of sodium carboxymethyl cellulose manufacturing lies in an unwavering commitment to innovation and sustainability. As new applications emerge, especially in bioplastics and pharmaceuticals, factories that invest in continuous research and development will lead the charge. Integration of digital twins and AI-based quality controls can revolutionize production efficiency, setting new benchmarks for quality and reliability. In summary, the distinguished factories are those that embed expertise, technology, and stringent quality controls into every facet of their operations. By committing to innovation, transparency, and compliance, these factories not only cement their authority in the market but also foster enduring trust with clients. For sodium CMC to continue playing a vital role as a versatile ingredient, these manufacturing practices must evolve in step with new market demands and environmental imperatives.

Post time: Januari . 19, 2025 00:53

Prev: