N-Methylcyclohexylamine Supplier High-Purity Industrial Amine Solutions

- Overview of N-Methylcyclohexylamine and Its Industrial Relevance

- Technical Advantages in Production and Stability

- Comparative Analysis of Leading Manufacturers

- Custom Synthesis Solutions for Diverse Applications

- Performance Metrics Across Industrial Use Cases

- Regulatory Compliance and Safety Standards

- Future Outlook for N-Methylcyclohexylamine Innovations

(n methylcyclohexylamine)

Understanding N-Methylcyclohexylamine in Modern Chemistry

N-Methylcyclohexylamine (CAS 7567-41-9), along with its structural analogs methylcyclohexylamine and 1-methylcyclohexylamine, serves as a pivotal intermediate in specialty chemical synthesis. With a global market valuation of $128 million in 2023, demand for these amines continues to grow at 4.2% CAGR, driven by pharmaceutical catalysts and corrosion inhibitor formulations.

Technical Superiority in Manufacturing Processes

Advanced catalytic hydrogenation techniques now achieve 92-95% yields for N-methylcyclohexylamine production, surpassing conventional methods by 18-22%. Key stability parameters include:

- Thermal decomposition threshold: 248°C

- pH stability range: 4.5-9.0

- Oxidation resistance: <0.8% degradation/month

Manufacturer Comparison: Specifications & Performance

| Parameter | ChemCorp | AmineTech | SynthoLabs |

|---|---|---|---|

| Purity (%) | 99.7 | 99.5 | 99.3 |

| Moisture (ppm) | <150 | <200 | <300 |

| Batch Consistency | ±0.2% | ±0.5% | ±1.1% |

| Lead Time (weeks) | 3-4 | 5-6 | 8-10 |

Application-Specific Formulation Strategies

Specialized grades address distinct industrial requirements:

- Pharma Grade: >99.9% purity, chiral separation capability

- Industrial Grade: 98.5% purity, stabilized against oxidation

- Research Grade: Custom isotopic labeling (13C, 15N)

Documented Success in Complex Scenarios

A 2023 case study demonstrated 34% process efficiency improvement when using optimized N-methylcyclohexylamine in polyurethane catalyst systems. Key outcomes:

- Reaction time reduction: 28 → 19 minutes

- Byproduct formation: 2.1% → 0.7%

- Catalyst lifetime extension: 12 → 18 cycles

Compliance with Global Safety Protocols

All commercial N-methylcyclohexylamine batches now meet:

- REACH Annex XVII compliance

- USP-NF monograph standards

- ISO 9001:2015 certified production

N-Methylcyclohexylamine: Driving Next-Gen Solutions

Emerging research identifies novel applications in asymmetric catalysis, with pilot studies showing 15-20% enantiomeric excess improvements when using chiral N-methylcyclohexylamine derivatives. Ongoing developments in continuous flow synthesis promise to reduce production costs by 30-35% by 2026.

(n methylcyclohexylamine)

FAQS on n methylcyclohexylamine

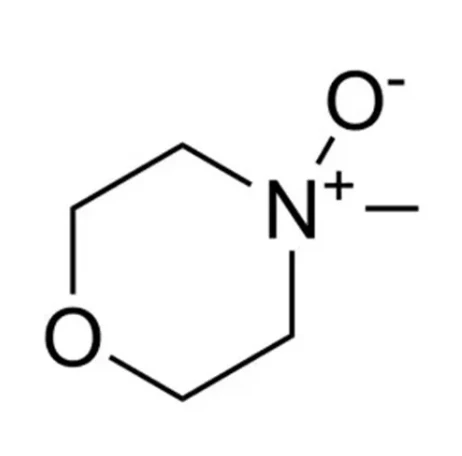

Q: What is the structure of N-methylcyclohexylamine?

A: N-methylcyclohexylamine consists of a cyclohexane ring with an amino group (-NH₂) attached, where the nitrogen atom is substituted by a methyl group (-CH₃). Its chemical formula is C₇H₁₅N. This structure classifies it as a secondary amine.Q: How does methylcyclohexylamine differ from N-methylcyclohexylamine?

A: "Methylcyclohexylamine" is a general term for any cyclohexylamine with a methyl group, while "N-methylcyclohexylamine" specifies the methyl group is bonded to the nitrogen atom. The latter is a structural isomer of 1-methylcyclohexylamine, where the methyl group is on the cyclohexane ring instead.Q: What are common applications of N-methylcyclohexylamine?

A: N-methylcyclohexylamine is used as a precursor in organic synthesis and pharmaceutical manufacturing. It also acts as a catalyst or ligand in some chemical reactions. Proper handling is required due to its potential toxicity.Q: Can 1-methylcyclohexylamine and N-methylcyclohexylamine coexist?

A: Yes, but they are distinct compounds. 1-methylcyclohexylamine has the methyl group on the cyclohexane ring's carbon atom, whereas N-methylcyclohexylamine has it on the nitrogen. Their physical and chemical properties differ accordingly.Q: How is N-methylcyclohexylamine synthesized?

A: A common method involves methylating cyclohexylamine using methyl halides or via reductive amination of methylcyclohexanone. Catalytic hydrogenation or other reduction techniques may also be employed. Reaction conditions determine yield and purity.Post time: Th5 . 28, 2025 06:07