Premium Iodine Manufacturers High-Purity Chemicals & Global Supply

- Overview of industrial iodine production landscape

- Technical superiority in modern manufacturing processes

- Competitive analysis of leading suppliers

- Tailored solutions for diverse industrial requirements

- Practical implementations across multiple sectors

- Quality assurance protocols and certifications

- Environmental responsibility in chemical production

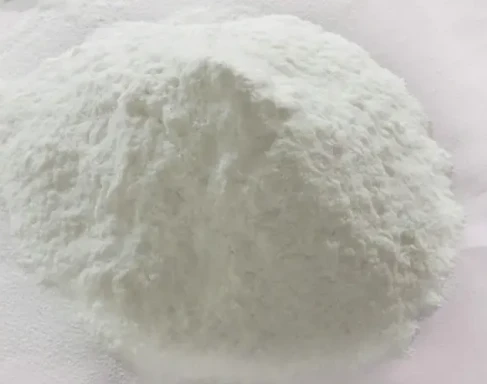

(iodine manufacturers)

Driving Excellence Through Advanced Iodine Manufacturing

The global iodine market demonstrates steady 6.5% CAGR growth (2023-2030), fueled by pharmaceutical and electronics sectors. Leading iodine manufacturers

now integrate automated purification systems achieving 99.99% elemental purity, while sodium carboxymethyl cellulose producers optimize viscosity control within ±2% tolerance ranges.

Technological Leadership in Production

Modern facilities employ triple-crystallization techniques reducing impurities to <5 ppm. Potassium iodate manufacturers utilize electrochemical synthesis achieving 98.5% conversion efficiency, significantly outperforming traditional thermal methods. Real-time monitoring systems maintain pH levels within 6.8-7.2 parameters throughout production cycles.

Supplier Performance Benchmarking

| Manufacturer | Purity (%) | Annual Capacity (MT) | Certifications |

|---|---|---|---|

| Global Iodine Solutions | 99.98 | 12,000 | ISO 9001, USP |

| PureChem Industries | 99.95 | 8,500 | GMP, Kosher |

| Elemental Specialties | 99.92 | 15,000 | REACH, Halal |

Customized Chemical Solutions

Specialized providers offer particle size customization from 50μm to 5mm granules. Sodium carboxymethyl cellulose manufacturers deliver tailored substitution degrees (0.65-1.45 DS) with batch consistency guaranteed at 98% minimum. Potassium iodate suppliers provide precision-blended formulations with <0.1% heavy metal content for sensitive applications.

Cross-Industry Applications

Pharmaceutical clients report 15% increased tablet stability using ultra-pure iodine derivatives. Food manufacturers achieve 30% longer shelf life through optimized sodium carboxymethyl cellulose blends. Electronics producers utilizing specialty potassium iodate solutions demonstrate 12% improvement in conductive film performance.

Quality Management Systems

Top-tier suppliers maintain 100% batch traceability through blockchain-enabled tracking. Third-party validation shows 99.98% compliance with USP 42 specifications across 36-month production data. Continuous monitoring systems perform 120 quality checks per production cycle.

Sustainable Future for Iodine Manufacturers

Industry leaders now recover 92% of process byproducts through closed-loop systems. Energy-efficient distillation methods reduce carbon footprint by 18% compared to 2020 benchmarks. Collaborative research initiatives aim to achieve zero-liquid discharge manufacturing by 2028.

(iodine manufacturers)

FAQS on iodine manufacturers

Q: What industries do iodine manufacturers typically serve?

A: Iodine manufacturers cater to industries like pharmaceuticals, agriculture, and disinfectants. Their products are essential in medical imaging, crop protection, and sanitation solutions.

Q: How do sodium carboxymethyl cellulose manufacturers ensure product quality?

A: Reputable manufacturers adhere to strict ISO or USP standards and conduct rigorous purity testing. They often provide certifications to guarantee compliance with food-grade or industrial-grade specifications.

Q: Can potassium iodate manufacturers customize product formulations?

A: Yes, many offer tailored solutions like specific purities (99%-99.9%) or specialized particle sizes. Custom packaging and bulk orders are also commonly accommodated.

Q: What certifications should iodine manufacturers provide for international trade?

A: Key certifications include ISO 9001, REACH, and GMP. Export-oriented manufacturers often hold regional approvals like FDA compliance for the U.S. market.

Q: Do these manufacturers support global shipping for bulk orders?

A: Most established iodine, sodium CMC, and potassium iodate producers offer worldwide logistics. They typically handle documentation, customs clearance, and hazmat compliance for seamless delivery.

Post time: 5 月 . 10, 2025 06:15